02 กันยายน 2568

ผู้ชม 394 ผู้ชม

ระงับการขายสินค้านี้เป็นการชั่วคราว

Sales of this product have been temporarily suspended.

Lead Fluid DMD25-T peristaltic pump head mainly meets higher requirements such as high precision filling and large flow and low pulsation. The overall uses of aluminum alloy and SS304 material, excellent mechanical properties.

Flow: 0.058~4200mL/min

Description

♦ Lead Fluid DMD25-Tperistaltic pump head flow range 0.58~4200mL/min, It mainly meets higher requirements such as high precision filling and large flow and low pulsation.

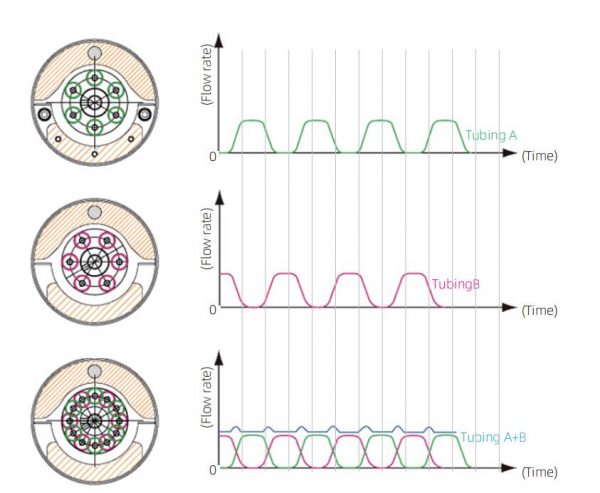

♦ The transmission smoothness is greatly improved by the double line pulsation complementary method.

♦ Elastic upper block structure reduces flow attenuation rate and greatly prolongs the service life of pump tube.

♦ Three pump heads can cascade to form three channels,increase productivity.

♦ The overall uses of aluminum alloy and SS304 material, excellent mechanical properties.

Pump Head Material

|

Shell

|

Aluminum alloy

|

|

Roller

|

SS304

|

|

Roller Axis

|

SS304

|

|

upper block

|

Aluminum alloy

|

Flow Rate Parameters

|

Tube material : Silicone, Pharmed, Viton, Norprene A-60-G/F Wall thickness 2.4mm

|

|||||||

|

ID(mm)

|

1.6

|

2.4

|

3.2 | 4.8 |

6.4

|

7.9

|

9.6

|

|

Tube

|

114#

|

119#

|

116#

|

15#

|

24#

|

35#

|

36#

|

|

mL/rpm

|

0.58

|

1.2

|

2.1

|

4.0

|

7.0

|

9.0

|

12.0

|

|

mL/min (continuous working maximum 350rpm)

|

201

|

426

|

752

|

1400

|

2450

|

3150

|

4200

|

The above flow data wer e obtained from the tests using a silicone tube to transfer pure water

under normal temperature and pressure conditions in the Leif labor atory. This data is f or

reference only.

Tube Installation

Specifications

|

Speed Range

|

0.1~350rpm

|

|

Flow Range

|

0.058~4200mL/min

|

|

Tube

|

114#,119#,116#,15#,24#,35#,36#

|

|

Channel

|

1

|

|

Roller

|

6

|

|

Pressure tube Structure

|

Elastic self-adaptation

|

|

Transmission Pressure

|

≤0.12MPa

|

|

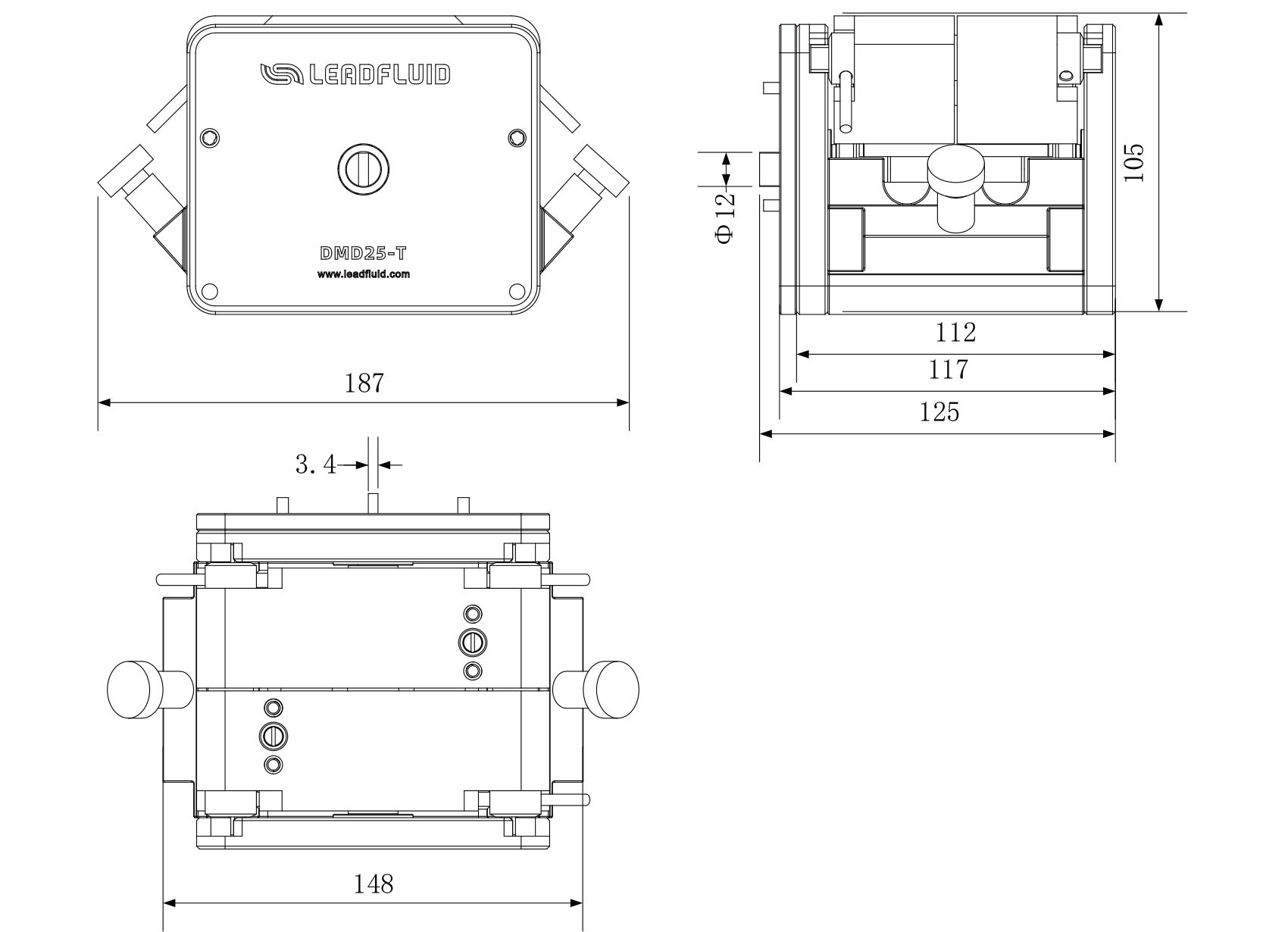

Dimension

|

187x105x125mm

|

|

Net Weight

|

2.8kg

|

Pulsation Complementare Schematic Diagram

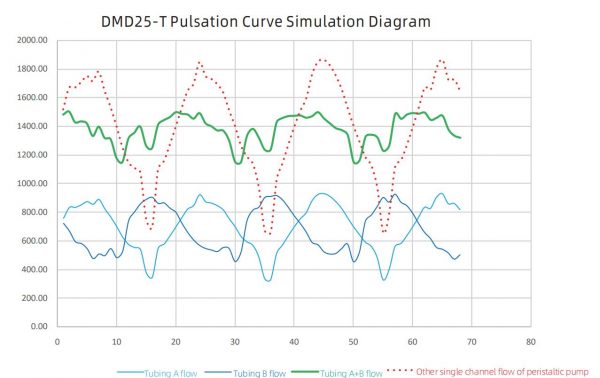

Pulsation Curve Simulation Diagram

When DMD25 is an A+B dual pipeline, under the same environmenta l conditions, compare the flow pulsation curve of the mixed pipeline with that of a single pipeline with the same flow rate.

Dimension

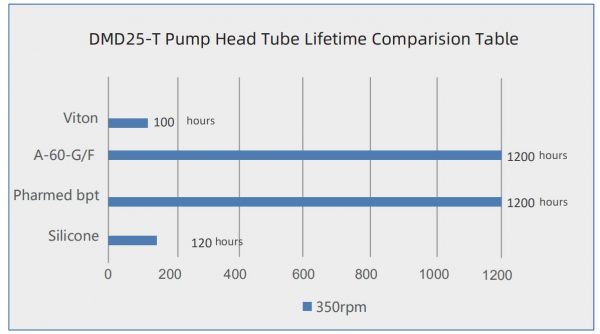

Tube Lifetime Comparision Table

Notes:

The above data are all test results obtained by Lead Fluid laboratory under normal temperature and

pressure for the transmission of pure water, which are for reference only; the actual service life may

be affected by specific factors such as pressure, temperature, medium characteristics, tube batch

and wall thickness; for specific problems, please contact Lead Fluid engineers to get better technical support.

Statement:The final explanation right of above information belongs to Lead Fluid.