21 ตุลาคม 2567

ผู้ชม 979 ผู้ชม

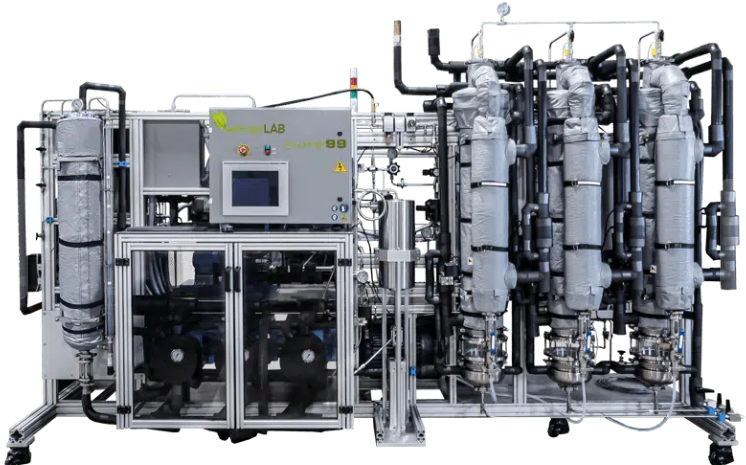

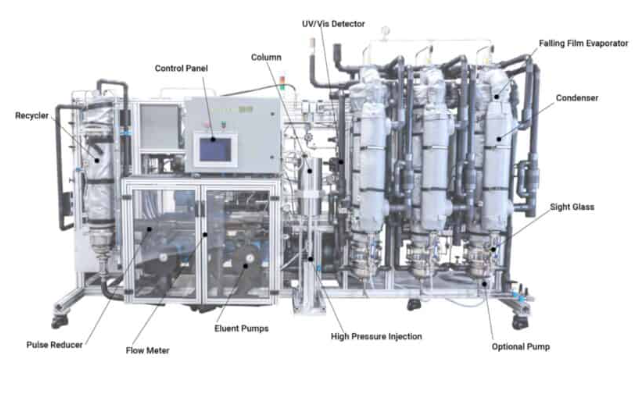

extraktLAB’s pure99 HPLC chromatography system is an automated, high-pressure liquid chromatography machine for the separation and purification of botanicals and active pharmaceutical ingredients. The chromatography machine is used to separate cannabinoids in the complex botanical matrix.

Key Applications:

- Separation of Minor Cannabinoids

- Separation of Nutraceutical or Pharmaceutical API from Botanical Extract

- THC/CBD Remediation

- THC Isolation

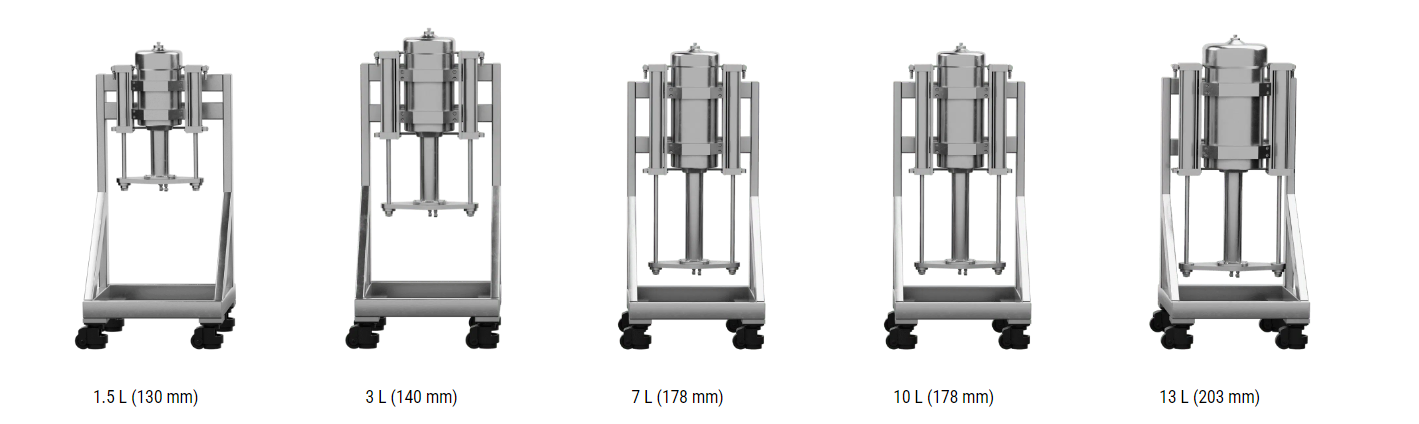

pure99x Column Upgrades

pure99 Stand Alone Columns provide separation flexibility that is required for every operation. The high maximum pressure and the variable column length allow optimization of the plate number and retention time. The unit comes as a complete assembly on casters that interfaces with the pure99 to control packed bed compression and provide eluent flow and sample injection.

All columns stand alone and have casters, with the same dimensions of: 60.96 cm x 60.96.cm x 132 cm. Columns are manufactured in the USA by United Science

| Max Column Volume 1.5 L |

Max Column Volume 3 L |

Max Column Volume 7 L |

Max Column Volume 10 L |

Max Column Volume 13 L |

| Materials: 316 Stainless Steel, PTFE | Materials: 316 Stainless Steel, PTFE, Viton | Materials: 316 Stainless Steel, PTFE, Viton | Materials: 316 Stainless Steel, PTFE, Viton | Materials: 316 Stainless Steel, PTFE, Viton |

| Inside Diameter: 130 cm |

Inside Diameter: 140 cm |

Inside Diameter: 178 cm |

Inside Diameter: 178 cm |

Inside Diameter: 203 cm |

| Max Pressure: 172 bar |

Max Pressure: 344 bar |

Max Pressure: 195 bar |

Max Pressure: 195 bar |

Max Pressure: 284 bar |

pure99x FEATURES & BENEFITS

- Closed Loop Solvent Recycling

- High Pressure Column

- Large Diameter Column for Loadability

- Binary Online Solvent Gradient Mixing

PROCESSING POWER:

Up to 7 L/min Flow Rate; Diameter column: 13.6 cm; User packable; 2,500 psi high pressure columns; Built-in solvent recovery falling film distillation; High pressure injection

GMP COMPLIANCE:

21 CFR Part 11 compliant software; Sensor certifications; Material certifications; inert and chemically stable polymeric seals; UL 698A, Listed; ATEX II and C1D2 Compliant; Normal, chiral, and reverse phases

PROCESSING CONTROL:

Automated for batch operation; Intrinsically safe thermocouples; Allen Bradley user interface; Eluent density control; Coriolis and turbine meter flow control; Up to two UV/VIS detectors; Closed loop solvent recycling; Method, sequence, and data acquisition software

General Specifications

| Dimensions (inches) | L157″ x W45″ x H93″ |

|---|---|

| Unit Weight (pounds) | 4500 |

| Sound Pressure (db) | 40-50 |

CERTIFICATIONS:

UL 698A, Listed; ATEX II and C1D2 Compliant; Wetted materials FDA approved; ASME 316SS

REQUIRED, SOLD SEPARATELY:

Chiller Requirement: 52kW, 15 ton capacity, 460v/3ph/37amp; Heater Requirement: 48kW, 200 GPM, 460v/3ph/37amp

ALSO AVAILABLE, SOLD SEPARATELY:

GMP Documentation Package; Commissioning and Training Package; Maintenance Package (12 Months),

WARRANTY:

12 months for quality, labor, parts, and workmanship on United Science equipment.