02 กันยายน 2568

ผู้ชม 674 ผู้ชม

ระงับการขายสินค้านี้เป็นการชั่วคราว

Sales of this product have been temporarily suspended.

Description

Introduction

• High-quality material selection, sanitary and non-toxic, high strength, good flexibility, and excellent resistance to chemical corrosion.

• The pump head utilizes a spring-loaded tube mounting structure that provides long tube life and high precision flow, the proper pressure can be obtained by adjusting the pressure tube unit.

• Adjusting the pressure tube device allows obtaining the appropriate pressure.

• The tube is easy and quick to install, and it can be adapted to various specifications, meeting a wide range of application requirements.

• Suitable for low-flow applications, it can be used as an ODM matching accessory in various instruments and equipment.

Parameters

Motor Type: DC Brushless motorReference Flow: See the flow table

Channel Number: 1

Number of Rollers: 4 rollers

Rotation Direction: Clockwise/Counterclockwise rotation

Lift Head: 8 m

Adaptable Tube Wall Thickness: 1.6 mm

Adaptable Tube ID: 14#(1.6mm), 19#(2.4mm), 16#(3.2mm), 25#(4.8mm)

Material of Tube: Silicone, Pharmed

Method of Tube Installation: Tube connectors

Pressure Tube Type: Spring adjustable

Pump Head Pressure Block Material: PVDF

Pump Head Cover Material: PET

Pump Head Roller Material: PVDF

Pump Head Life: ≥1000h

Noise: ≤70dB (test environment noise ≤40dB, test product and noise meter horizontal distance of 1 meter)

Weight: 390g (without tube)

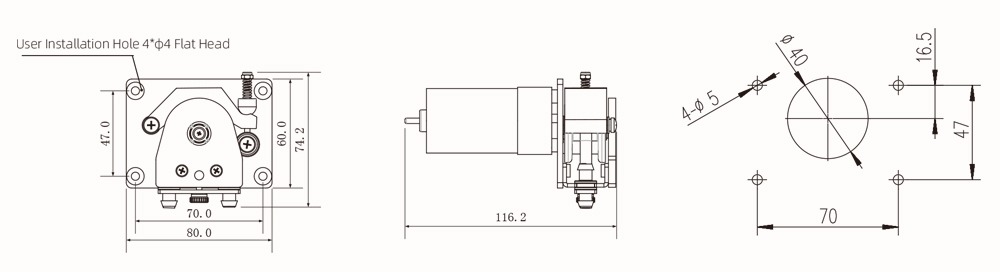

Dimensions: (L×W×H) 116.2*80*60(mm)

Working Environment: Temperature 0- 40°C, relative humidity<80% RH

Storage Environment: Ambient temperature of -20 ~ +50 °C, relative humidity of not more than 95% of the clean and well-ventilated environment, the air shall not contain corrosive, flammable gases, oil mist, dust.

Suitable Tube Model and Flow Rate Reference Table

DW15-1 Pump Head Speed and Flow Comparison Table (unit: mL/min)| Speed (r/min) |

Tube No. (ID) | |||

| 14#(1.6mm) | 19#(2.4mm) | 16#(3.2mm) | 25#(4.8mm) | |

| 0.1 | 0.012 | 0.024 | 0.041 | 0.080 |

| 1 | 0.12 | 0.24 | 0.41 | 0.80 |

| 20 | 2.40 | 4.80 | 8.20 | 16.00 |

| 40 | 4.80 | 9.60 | 16.40 | 32.00 |

| 60 | 7.20 | 14.40 | 24.60 | 48.00 |

| 80 | 9.60 | 19.20 | 32.80 | 64.00 |

| 100 | 12.00 | 24.00 | 41.00 | 80.00 |

| 200 | 24.00 | 48.00 | 82.00 | 160.00 |

| 300 | 36.00 | 72.00 | 123.00 | 240.00 |

| 400 | 48.00 | 96.00 | 164.00 | 320.00 |

For speeds above 100rpm, it is recommended to use intermittent operation. The intermittent operation mode involves running for 0.7 seconds and then stopping for 0.3 seconds.

The above data is obtained from the test of purified water with a Lead Fluid tube under normal and pressure conditions in the laboratory. This data is for reference only.

Due to pressure in actual use, temperature, medium characteristics, tube material and other specific factors, the specific situation needs to consult our engineers.

Product Structure & Usage Method

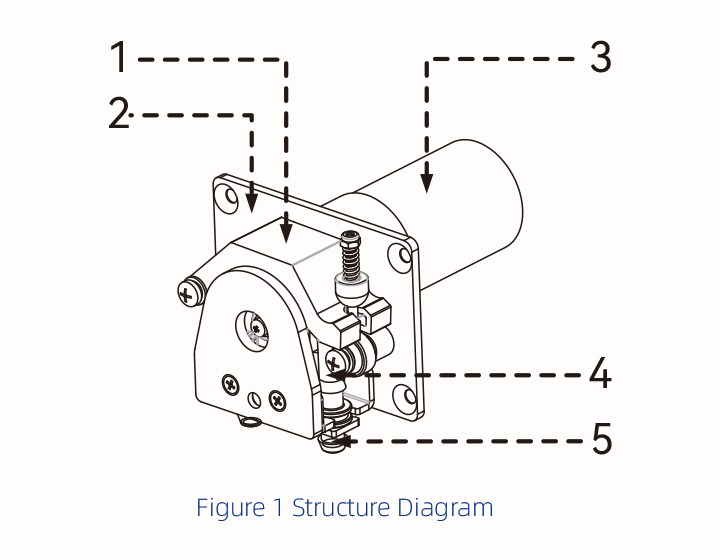

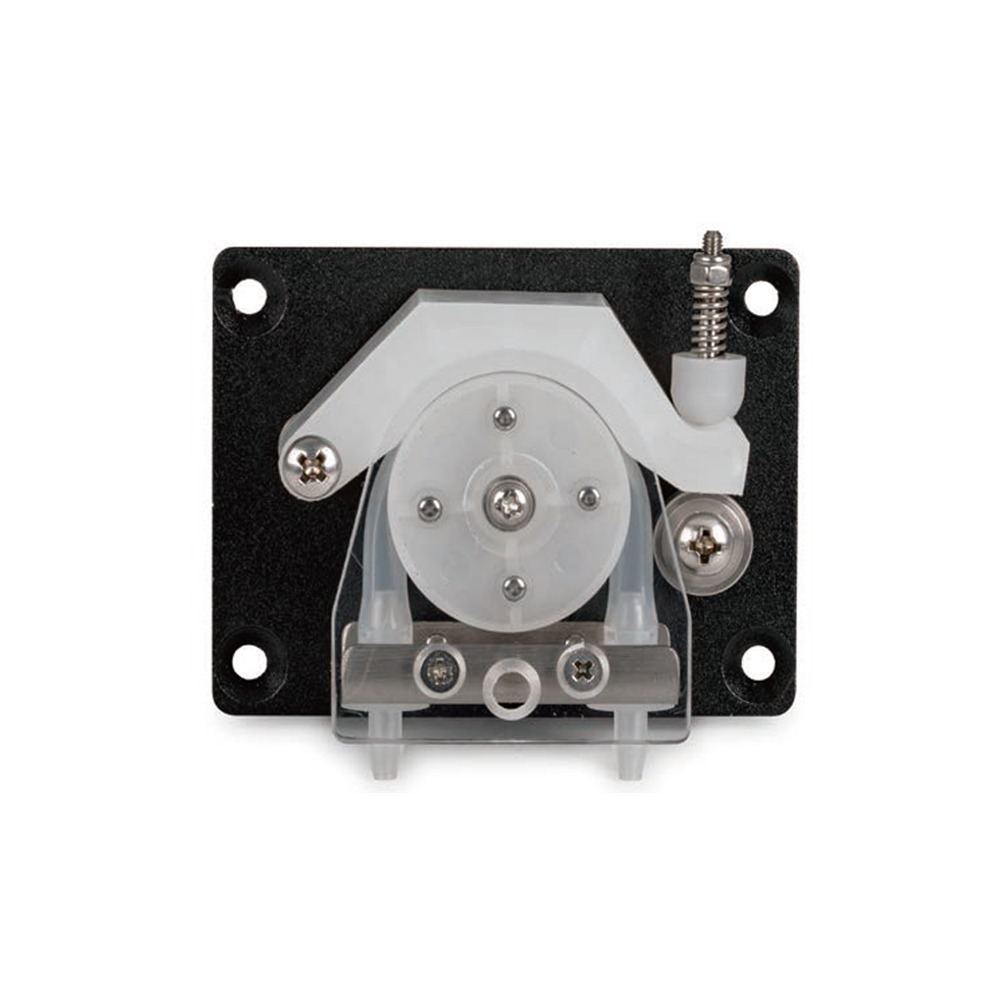

Product Structure

Component Name and Function

1.Pump Head Pressure Block: Squeezes the tube along with the roller assembly.

2.Mounting Plate: Connects the motor to the pump head bracket and allows the product to be installed on other devices.

3.Motor: Provides power.

4.Tube: Made of silicone or pharmed material.

5.Tube Connector: Secures the tube in place.

Usage Method

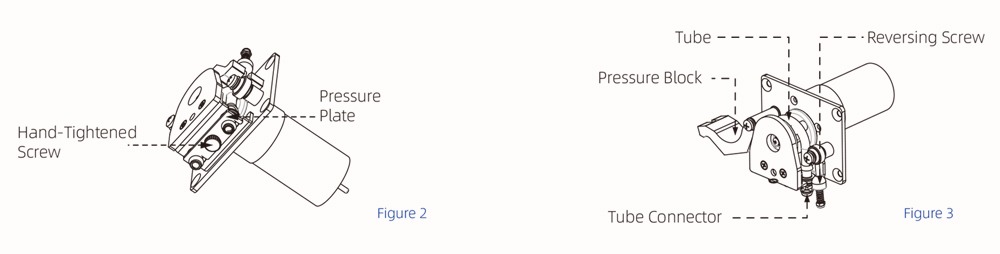

Disassembling the Tube

1.Unscrew the hand-tightened screw counterclockwise, then rotate the pressure plate clockwise while applying

downward force to remove it, as shown in Figure 2.

2.Remove the reversing screw, then lift the pressure block upward, and take out the tube and tube connector, as shown in Figure 3.

Install Tube

Reverse the order of disassembly.

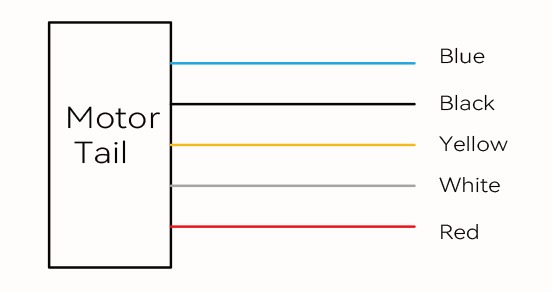

Electrical parameters

Motor Wire Color Description

1.Blue: Connect to 0-5V signal for speed regulation (if you don’t use the speed regulation function,

you can short-circuit the blue speed regulation wire and the black GND wire, and the motor will run

at the highest speed)

2.Black: GND power negative access

3.Yellow: FG Hall signal feedback (feedback 6 pulses per motor revolution)

4.White: CW/CCW forward and reverse switching

5.Red: VCC power positive access

| Parameter | Model | |||

| W100A2DW15 -1-24V |

W100A2DW15 -1-12V |

W400A2DW15 -1-24V |

W100A2DW15 -1-24V |

|

| Power Supply | DC24V | DC12V | DC24V | DC12V |

| Motor Cable Length | 280±15mm | 280±15mm | 280±15mm | 280±15mm |

| No-load Maximum Speed | 110±10rpm | 108±10rpm | 395±10rpm | 417±10rpm |

| No-load Current | 0.155A | 0.36A | 0.8A | 0.472A |

| Load Current | 0.94A | 1.54A | 1.53A | 1.78A |

| Load Torque | 10Kg.cm | 8Kg.cm | 4Kg.cm | 2.5Kg.cm |

| Load Power | 10w | 8w | 16W | 10W |

| Torque When Motor Losses Speed | 26Kg.cm | 20Kg.cm | 15Kg.cm | 7Kg.cm |

| Current When Motor Losses Speed | 2.14A | 2.13A | 4.25A | 3.5A |

Dimension

unit: mm