02 กันยายน 2568

ผู้ชม 911 ผู้ชม

ระงับการขายสินค้านี้เป็นการชั่วคราว

Sales of this product have been temporarily suspended.

Description

Introduction

•The entire pump head is made of high-strength plastic material, with high rigidity and excellent wear resistance.

•The pump head adopts a unique rotating cassette design, which can be disassembled and assembled without tools, making it easy to replace the pump tube and clean and maintain it. There are two tube installation methods: tube connectors and tube stoppers.

• Quick-installation pump head, the inlet and outlet ends can be installed in any direction to adapt to different working conditions.

• Small size, easy to install and simple to operate.

• Suitable for a variety of small instruments and equipment, to meet the needs of micro-injection, rinsing, and liquid drainage.

Parameters

Motor Type: Brushless DC motor

Power Supply: DC12V

Wattage: 6W

Max Speed: 110rpm±10%

Reference Flow: See the flow table

Channel Number: 1

Number of Rollers: 3 rollers

Rotation Direction: Clockwise/Counterclockwise rotation

Lift Head: 10 m

Adaptable Tube Wall Thickness: 0.85 mm

Adaptable Tube ID: 1.02mm, 2.06mm, 2.79mm

Material of Tube: Silicone, Pharmed

Method of Tube Installation: Tube connectors or tube stoppers

Pressure Tube Type: Fixed

Pump Head Shell Material: PC

Pump Head Roller Material: PET

Pump Head Life: ≥1000h

Noise: ≤60dB (test environment noise ≤40dB, test product and noise meter horizontal distance of 1 meter)

Weight: 116g (without tube)

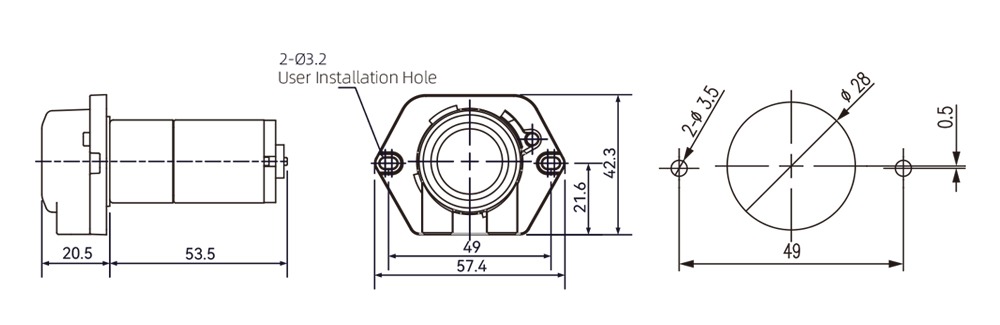

Dimensions: (L×W×H) 74*57.4*42.3(mm)

Working Environment: Temperature 0- 40°C, Relative humidity<85% RH

Storage Environment: Ambient temperature of -20 ~ +50 °C, relative humidity of not more than 95% of the clean and well-ventilated environment, the air shall not contain corrosive, flammable gases, oil mist, dust.

Flow Rate Reference

MM10 Pump Head Speed and Flow Comparison Table (unit: mL/min)

| Tube ID (mm) | Speed(r/min) | |||||

| 10 | 20 | 40 | 60 | 100 | 110 | |

| 1.02 | 0.47 | 0.95 | 1.89 | 2.84 | 4.73 | 5.17 |

| 2.06 | 1.46 | 2.93 | 5.85 | 8.78 | 14.63 | 16.06 |

| 2.79 | 3.06 | 6.12 | 12.24 | 18.35 | 30.59 | 33.66 |

For speeds above 100rpm, it is recommended to use intermittent operation. The intermittent operation mode involves running for 0.7 seconds and then

stopping for 0.3 seconds.The above data is obtained from the test of purified water with a Lead Fluid tube under normal and pressure conditions in the

laboratory. This data is for reference only.Due to pressure in actual use, temperature, medium characteristics, tube material and other specific factors,

the specific situation needs to consult our engineers.

Usage Method

Disassembly

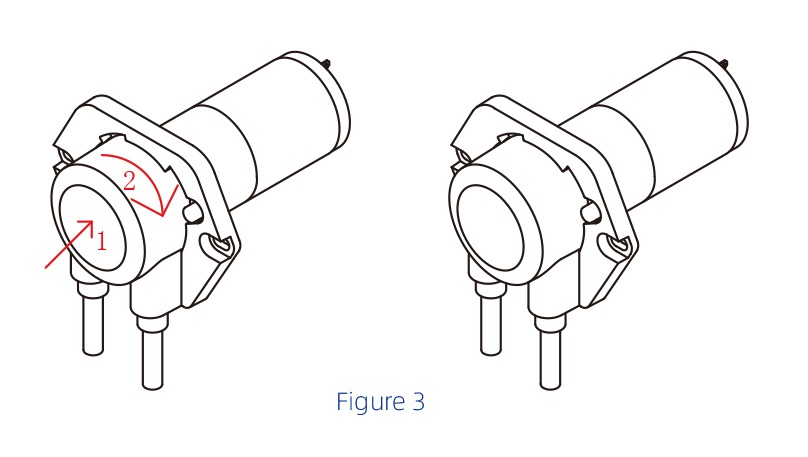

1. Press the snapper (Figure 1, No. 1).

2. Rotate the pump head cover counterclockwise to the limit position (Figure 1, No. 2).

3. Vertically remove the pump head cover facing yourself (Figure 1, No. 3).

Assembly

1. Place the tube over the three rollers and insert it into the front cover of the pump head. Note that the direction of the roller disc should match the illustration.

The illustration shows the tube fixed with a stopper, and the tube clamp fixing method is the same. See Figure 2.

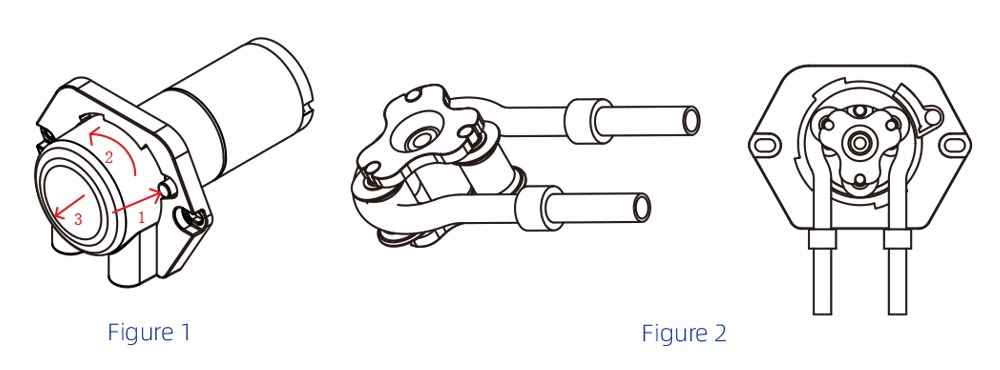

2. Insert it into the motor shaft in the original direction of disassembly (Figure 1, No. 3), rotate clockwise, and wait for the pump head snapper to lock with the pump head front cover in place. At this point, the inlet/outlet of the pump head should be perpendicular to the two screw mounting holes on the pump head mounting plate. See Figure 3.

Dimensions

unit:mm