24 กรกฎาคม 2568

ผู้ชม 1052 ผู้ชม

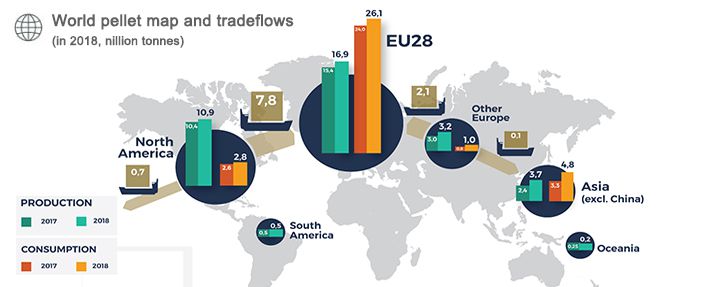

Due to the shrinking of oil resources and the increasingly serious problems of global warming, the development and utilization of renewable and clean energy has become the consensus of all countries in the world to alleviate the energy crisis and climate change. Biomass pellet fuel is a renewable clean energy, in the last decade under the attention of the international community and governments around the world biomass pellet fuel industry has developed rapidly.

Top Pick GEMCO Wood Pellet Mill - ZLSP420

ZLSP-420 wood pellet mill machine has been recognized as the most cost effective biomass pellet machine among GEMCO pellet mill. It’s designed with flat die and has been equipped with overload protection device, which allows easy and safety operation. (Read more: Flat Die Pellet Mill >>)

ZLSP 420 Wood Pellet Mill Machine

GEMCO ZLSP420 pellet mill is suitable to process various biomass raw materials into high density wood pellet fuels like wood chips, sawdust, straw, rice husk, barks, cotton stalks, etc.. (You may also like: Straw Pellet Machine Price >>)

Raw Materials for Gemco Pellet Mill

ZLSP420 Pellet Mill Types and Structure

In order to adapt to diferent operating environments, GEMCO ZLSP420 pellet mill also provides three kinds of power supply, motor drive, diesel engine drive, PTO drive. The detailed technical parameters of every ZLSP 420 model is as below. If you are interested in it, please contact us to get the latest promotion price!

Factory Price Wood Pellet Mill

| Type | Power | Pellet Specification | Capacity | Weight | Dimensions |

|---|---|---|---|---|---|

| ZLSP 420B | 37kw | 6, 8, 10 mm | 400-600 kg/h | 1100 kg | 1630*620*1400 mm |

| ZLSP 420A | 46kw (62hp) | 6, 8, 10 mm | 400-600 kg/h | 1200 kg | 2590*660*1400 mm |

| ZLSP 420P | 37-48 kw | 6, 8, 10 mm | 400-600 kg/h | 700 kg | 1500*850*1400 mm |

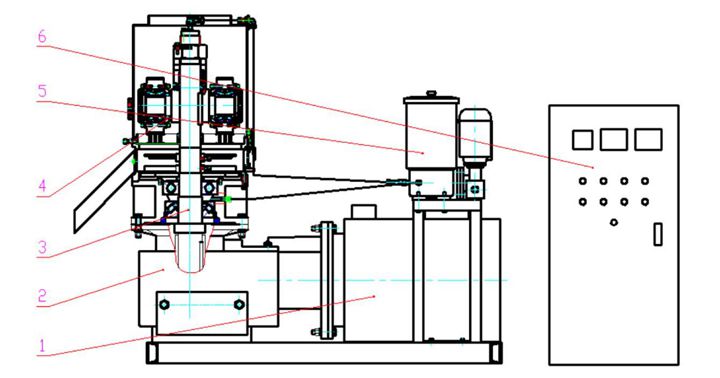

Motor-driven Pellet Mill - ZLSP 420B

ZLSP420B is an electric pellet mill that is composed of motor, reducer, drive part, molding part, self-lubrication and electronic control, etc.

1. Motor 2. Reducer 3. Drive part 4. Molding part 5. Self-lubrication 6. Electronic part

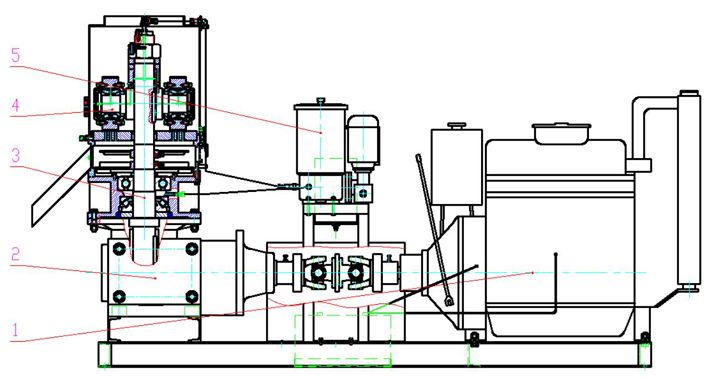

Diesel-driven Wood Pellet Mill - ZLSP 420A

ZLSP420A is a diesel pellet mill that is composed of diesel engine, reducer, drive part, molding part and self-lubrication, etc.

1. Diesel engine 2. Reducer 3. Drive part 4. Molding part 5. Self-lubrication

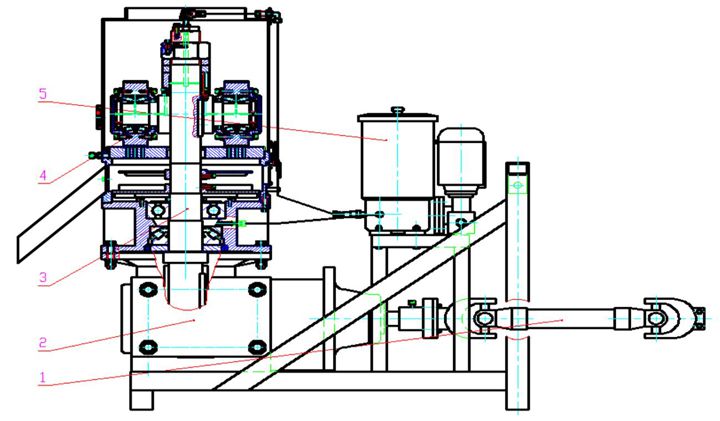

PTO Pellet Machine - ZLSP 420P

ZLSP420P is a PTO pellet mill that is composed of PTO, reducer, drive part, molding part and self-lubrication.

1. PTO 2. Reducer 3. Drive part 4. Molding part 5. Self-lubrication

Working Principle of ZLSP420 Pellet Mill

The pulverizing biomass raw materials will be squeezed out from the die hole under the function of ZLSP420 pellet mill die and roller. The cutter will cut them into pellets with a certain length. The pellet length can be guaranteed by adjusting the top and lower position of the cutter. The pellets will be sent out by the material rejection tray from the outlet port. (Read more: Biomass Pellet Production Line >>)

GEMCO Wood Pellet Mill at Factory Price

Feature of GMC-ZLSP420 Pellet Mill

- The whole machine will be delivered out. You can install it directly.

- ZLSP420B pellet mill is equipped with electric control cabinet. Connect the wire according to the installation drawing in order to make the motor rotating direction right.

- The device is equipped with self-lubrication device, ensure long-term normal operation of equipment.

- The pellet mil disc can be used on both sides. If the die is worn seriously, You can dismount it and use the other side of the die.

ZLSP 420B Biomass Wood Pellet Mill Pelletizing Video

Application of GEMCO Pelletizing Mill

Wood pellets making by pelletizing mill can gain heat energy by burning. The fuel pellets are widely used in life heating, power generation, stove, etc. Wood pellets are the alternative fuel of the non-renewable energy source like coal, fossil oil, natural gas, etc, which can not only save energy but also reduce the carbon elimination. Wood pellet is a kind of high-efficiency, clean renewable energy source.