02 เมษายน 2567

ผู้ชม 1315 ผู้ชม

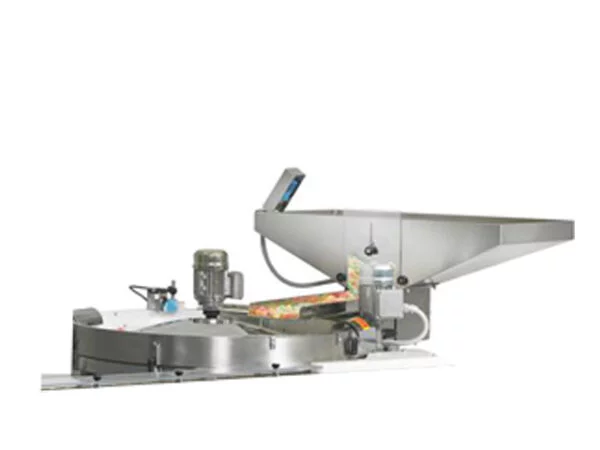

For all hot and cold sealing films

- Cross sealing system with six sealing jaws

- Up to 1800 packs per minute

- Automatic infeed guarantees a gentle product transport to the flow wrapper

- Easy to clean

| Size range | Length: 15 up to 50mm Width: 5 up to 50mm Height: 1 up to 30mm |

| Maximum film width | 150mm |

| Film material | All heat and cold sealable films |

| Capacity | Up to 1800 packs per minute |

All data are approximate only.

The flow wrapping machine CO90E, also known as “candy wrapper”, is mainly used for packing of candies and toffees, cookies, biscuits or wafers. For infeed of products such as mint candies or lollipops a sort of disk can be used. Via punched disk the products are isolated and led to the pusher chain of the wrapper. As an option, complete conveying and infeed systems can be used. These devices take the cookies directly from the oven, assort the products, isolate and lead them to the infeed of the flow wrapper. The products are conveyed in a gently way and are packed without the risk of being broken.