16 มกราคม 2567

ผู้ชม 1370 ผู้ชม

Typical applications of the UIP6000hdT include homogenization, emulsification, dispersing & particle fine milling, extraction, malaxation of olive oil, dissolving or sonochemical reactions such as sono-synthesis and sono-catalysis.

6000 Watts Ultrasound Power Built for Industrial Processing

This high-power system is particularly favorable for industrial processes in demanding environments and with limited spacing, since no additional cooling media, such as water or compressed air, are necessary. The special design of this system allows for its use under extreme operation conditions, such as dust, dirt, temperature and humidity. The ultrasonic processor consists of titanium and stainless steel. The oscillation-free flange has proven very useful for the integration into machines and plants. It has been adapted to the new technical conditions in terms of correct oscillation-behavior.

With a small footprint and its movable cabinet on wheels, the UIP6000hdT can be installed even in cramped confines.The modular concept of the UIP6000hdT provides you with a powerful and yet very space-saving system. The transducer and generator are housed separately from each other and are connected via cables. The self-contained design reduces the work required for installation, operation and maintenance to a minimum level. Multiple UIP6000hdT modules can be easily combined to form clusters with higher process capacities.

The UIP6000hdT with ultrasonic flow cell reactor and sound enclosure cabinet.

6kW Processing Capacity

Process Flow Rate

biodiesel transesterification 1.5 to 4m³/hr

emulsification, e.g. oil/water 0.5 to 2.5m³/hr

cell extraction, e.g. algae 0.15 to 1m³/hr

dispersing/deagglomeration 0.025 to 0.5m³/hr

wet milling and grinding 0.01 to 0.025m³/hr

In general, the flow cell as well as the ultrasonic transducer are located in a double-walled stainless steel cabinet that comes with a very effective sound insulation. If required, the UIP6000hdT can be used for the sonication of liquids in custom-specific reactors. Of course, the UIP6000hdT is capable to run continuously at full power output (24hrs/7days) like all ultrasonic systems from Hielscher Ultrasonics.

The UIP6000hdT at a glance

- 6000 watts powerful ultrasonicator

- reliable for heavy duty sonication processes

- 24/7 operation

- industrial grade

- colored touch display

- browse remote control

- automatic data recording of power, amplitude, sonication time, temperature, pressure

- integrated SD/USB ComboCard

- pluggable temperature sensor

- pluggable pressure sensor (optional available)

- LAN connection

- Ethernet connection

- no software installation

- automatic frequency tuning

Ultrasonic generator, transducer and flow cell are housed in a sound enclosure cabinet.

UIP6000hdT – High-Power Ultrasonic Homogenizer

As part of the Hielscher Ultrasonics industrial series, the UIP6000hdT is a robust 6kW ultrasonic processor for heavy-duty applications in rough industrial environments. Hielscher Ultrasonics industrial sonicators can deliver very high amplitudes. Amplitudes of up to 200µm can be easily continuously run in 24/7 operation. For even higher amplitudes, customized ultrasonic sonotrodes are available. The robustness of Hielscher ultrasonic equipment allows for 24/7 operation at heavy duty and in demanding environments.

The Hielscher UIP6000hdT cluster consists of up to 12x sonicators. This setup allows to compose a 72kW

powerful inline sonication system for high-performance inline processing.

Related Topics

- MultiSonoReactor for High-Throughput Inline Sonication

- UIP4000hdT – 4kW High Performance Ultrasonics

- Graphene Nanoplatelets Synthesized and Dispersed via Probe-Sonication

- Ageing and Oaking of Wines with Ultrasound

- Polyphenol-Rich Wines with Power-Ultrasound

- Various Solutions for Phosphorus Recovery from Municipal Sewage Sludge

Not sure which ultrasonic system is the most suitable for your process? The table below gives you an indication of the approximate processing capacity of our ultrasonicators:

Batch Volume Flow Rate Recommended Devices

0.5 to 1.5mL n.a. VialTweeter

1 to 500mL 10 to 200mL/min UP100H

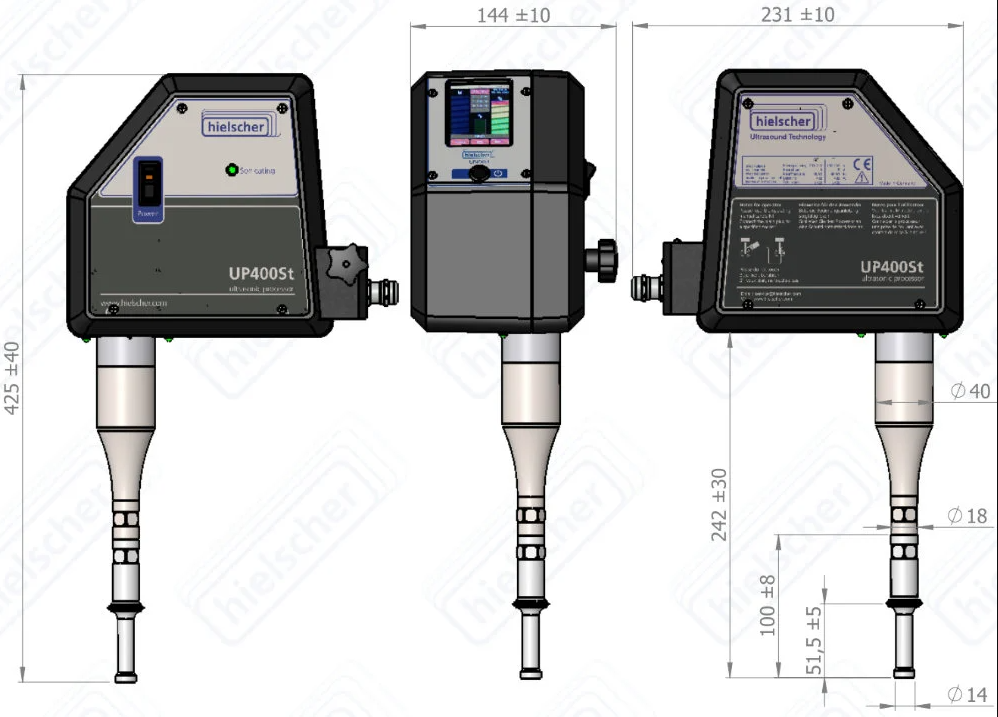

10 to 2000mL 20 to 400mL/min UP200Ht, UP400St

0.1 to 20L 0.2 to 4L/min UIP2000hdT

10 to 100L 2 to 10L/min UIP4000hdT

n.a. 10 to 100L/min UIP16000

n.a. larger cluster of UIP16000

Facts Worth Knowing

Basics of Ultrasonic Homogenization Ultrasonic homogenizers are used for dispersion, emulsification, wet-milling, nano- & micronization, extraction (from plants and cell tissues), synthesis and catalysis of chemicals (so-called sono-chemistry) as well as degassing. Ultrasonic homogenization is often used as umbrella term that includes all these fore-mentioned applications. The ultrasound-assisted homogenization is based on the working principle of acoustic caviation, which occurs when intense ultrasound waves are coupled into a liquid medium. Under the intense ultrasound waves, minute vacuum bubbles are generated in the medium, which grow over the high pressure / low pressure cycles of the ultrasound waves. At a certain point, when the micro-bubbles have reached an energetic status, at which they cannot absorb more energy, they collapse violently. This phenomenon of vacuum bubble implosion is called cavitation. The implosion of the vacuum bubbles generates shock waves, streaming / liquid jets, high shear, high temperature and pressure differentials with sufficient energy to break covalent bonds, flex molecules and induce chemical reactions.

Acoustic cavitation (generated by power ultrasound) creates locally extreme conditions, so-called sonomechanical and sonochemical effects. Due to these effects, sonication promotes chemical reactions leading to higher yields, faster reaction speed, new pathways, and improved overall efficiency.

For best results in the homogenization process, the ultrasonic processor and its setup can be optimized by changing the following variables:

- Amplitude (displacement of the sonotrode) and intensity

- Pressure

- Temperature

- Sonication vessel (batch or flow cell: size, geometry, flow rate)

Hielscher high performance ultrasonicators use piezoelectric generators made of lead zirconate titanate crystals. The vibrations are transmitted down a titanium horn tuned resonate at 19-26 kHz. From the horn the ultrasonic vibration is coupled via ultrasonic sonotrode (tip, probe) into the fluid medium. Hielscher offers ultrasonic processors with power ratings from 50 to 16,000 watts per ultrasonic unit and covers thereby the requirements from small lab ultrasonicators and bench-top devices up to pilot plant and fully commercial ultrasonic units for high volume throughput.Sophisticated Process Control for Optimal Sonication Results

Sonication conditions are crucial for output, process results and reproducibility of ultrasonic processes. Besides the precise control of ultrasonic power output, adjusted by amplitude and intensity, temperature, pressure and sonication time are important factors. Hielscher digital ultrasonic processors come with a plugable thermo-couple. A plugable pressure sensor is optionally available. Both sensors are connected with the ultrasonic generator, which is equipped with an internal SD card. The software of the ultrasonic device writes all process data (date, time, amplitude, ultrasonic energy, net energy, temperature, pressure) in a CSV file on the SD card. This makes your sonication runs comparable and reproducible.

For high amplitudes, a higher output power is required. Under increased load such as high viscosity of the medium or elevated pressure, an increased ultrasound power is needed to drive the sonotrode at a desired amplitude. The larger the front surface of the sonotrode (tip), the more power is required to let it resonate. With a larger sonotrode, larger volumes can be processed. Hielscher industrial sonotrodes and cascatrodes can deliver very high amplitudes. Amplitudes of up to 200µm can be easily continuously run in 24/7 operation. For even higher amplitudes, customized ultrasonic sonotrodes are available. The sturdiness of Hielscher ultrasonicators allows for 24/7 operation under heavy load and under demanding conditions.

For most ultrasonic processes, temperature of sonicated medium should be as low as possible for a low temperatures promotes the generation of intense cavitation. Hielscher offers ultrasonic flow cells and reactors with cooling jackets, which support the maintenance of optimal process temperatures. Flow cells and reactores are pressurizable, too. Under elevated pressures, more intense cavitation occurs. Therefore, Hielscher offers reactors that can easily pressurized up to 300atm.

Hielscher Ultrasonics manufactures ultrasonic probes of different sizes and shapes (e.g. cascatrodes), which allows to scale up all ultrasonic process results completely linear. With 16kW ultrasonic homogenizers and manifold types of sonotrodes and flow cell reactors, Hielscher is your long-term experienced partner for ultrasonic processes on industrial scale. Besides the variety of standard ultrasonicators, Hielscher designs and manufactures customized systems, too.