16 มกราคม 2567

ผู้ชม 1604 ผู้ชม

UIP1500hdT – Sonicator for Bench-top and Production

The sonicator UIP1500hdT bridges the gap between laboratory testing and the industrial processing of liquids. Its wide range adaptability and easy operation meet the requirements of research and development. The UIP1500hdT is built for heavy-duty operation in 24hrs/7days production processes under demanding conditions.

Seamless Scale-Up from Lab to Production

The ultrasonic processor UIP1500hdT is suitable for the sonication of many materials and a variety of processes, such as, nanomaterials, paint and ink, coatings, food and beverage, cosmetics, or chemical processes.

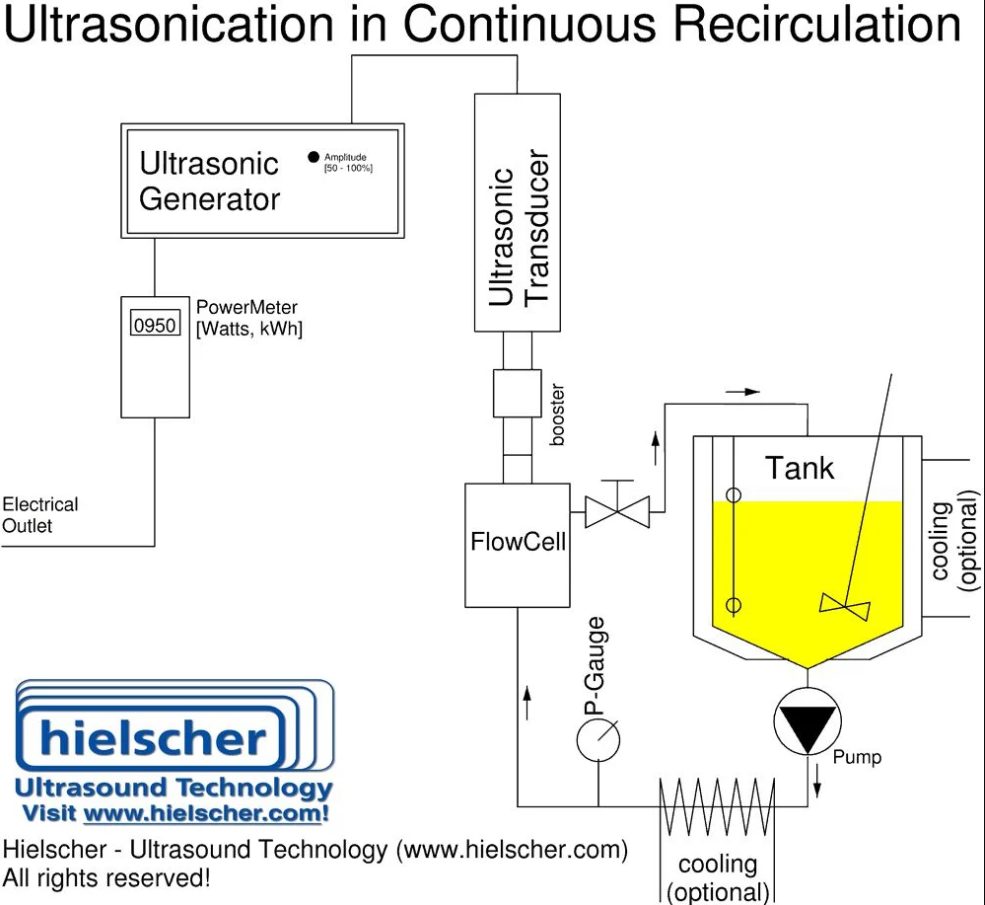

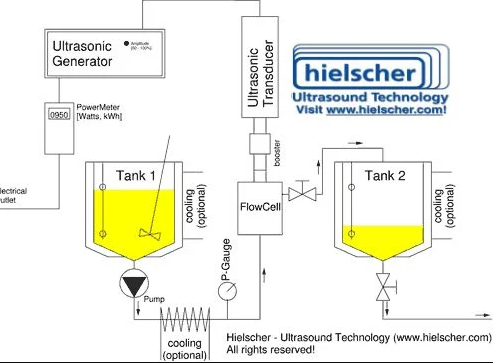

The UIP1500hdT is commonly used for inline sonication in a single pass or loop in order to obtain a better processing quality. Of course, it can be used for batch sonication, too. The UIP1500hdT allows for running at a wide range of ultrasonic parameter sets. You can vary the ultrasonic amplitude, the liquid pressure and the liquid composition, such as:

sonotrode amplitudes of up to 170 micron

- liquid pressures of up to 10 bars

- liquid flow rates of up to 15L/min (depending on the process)

- liquid temperatures of up to 80 degC (other temperatures on request)

- material viscosity of up to 100.000cP

This flexibility allows for finding the optimal process configuration. The UIP1500hdT offers you exact reproducibility and linear scaleability. Any sonication setup can be reproduced and can be used at continuous operation or can be scale up to any larger unit. We offer a wide range of accessories, like sonotrodes, boosters and flow cell reactors and sound protection boxes.

Sonicator UIP1500hdT (1500 watts ultrasound power) with flow-through reactor FC2t500k

Typical flow rates for the UIP1500hdT are between 0.5 and 6.0L/min or 1 to 8m³/day. For higher production capacity, we recommend using either multiple units or one of the more powerful ultrasonic homogenizers:

- UIP2000hdT (2000W, 20kHz)

- UIP4000hdT (4000W, 20kHz)

- UIP6000hdT (6000W, 20kHz)

- UIP10000 (10000W, 18kHz)

- UIP16000 (16000W, 18kHz)

High-Performance Sonicator with Industrial Grade and Outstanding Efficiency

While the UIP1500hdT can be used in the lab, it is designed and built for industrial processing. It requires little maintenance, is easy to setup and simple to clean and to sanitize. We offer special flow cell reactors meeting the advanced CIP (clean-in-place) and SIP (sterilize-in-place) requirements. The transducer of the UIP1500hdT is IP64 grade and withstands dirt, dust, moisture or outside operation.

Due to its outstanding transformation efficiency, the transducer does not require forced cooling, such as cooling water or compressed air. It is built into a closed housing and there are no vents in the transducer case. Lower heat losses mean, that more energy is transmitted into the liquid, resulting in a better sonication. The overall energy efficiency of the UIP1500hdT is approx. 80-90% from the power plug into the liquid (click at the image above to enlarge the chart).

Full Control and High-Performance Ultrasound Mixing

Of course, the UIP1500hdT can be run at 1500W continuously. It delivers the power at a controlled amplitude level, so that the magnitude of the mechanical ultrasonic vibrations at the sonotrode is constant under all load conditions. You can change the amplitude from 20 to 100% at the generator and by using various booster horns. The set amplitude is constant, while sonicating any material at any pressure. This feature gives you full control over the most important sonication parameter: Amplitude.

Related Topics

- Ultrasonic Extraction of Polyphenols from Baggibuti (Stachys parviflora)

- Ultrasonic Homogenizers for Liquid Processing

- Ultrasonicators and Probes for Liquid Processing

- Ultrasonic Extraction and Preservation

- Ramp-up Slow and Insufficient Manufacturing Processes

- How to Make Nanofluids

Install the UIP1500hdT in Various System Setups

All Hielscher probe-type sonicators can be installed in various flow-through setups. Single-pass recirculation, multiple-pass and discrete recirculation flow-through reactors are two different approaches to handling the flow of reactants and products for homogenization, chemical or biochemical processes. Hielscher sonicators can be installed in all of these flow systems.

Applications of the Industrial Sonicator UIP1500hdT in Research and Science

The UIP1500hdT, a 1500 watts powerful high-performance sonicator, is a popular ultrasonic machine, frequently used in pilot setups and industrial production. Below you can find a selection of scientific articles featuring the ultrasonic processor UIP1500hdT. The articles cover topics such as from ultrasonic emulsification and the production of nano-emulsions, the exfoliation of zeolites, nano-material processing, sono-crystallization, and the degassing of drilling fluids. If you are looking for a specific application and related scientific references, please contact us.

Mahmood Amani, Salem Al-Juhani, Mohammed Al-Jubouri, Rommel Yrac, Abdullah Taha (2016): Application of Ultrasonic Waves for Degassing of Drilling Fluids and Crude OilsApplication of Ultrasonic Waves for Degassing of Drilling Fluids and Crude Oils. Advances in Petroleum Exploration and Development Vol. 11, No. 2 , 2016.

Ye, Yubin; Silvana Martini (2015): Application of high-intensity ultrasound to palm oil in a continuous system. Journal of agricultural and food chemistry Vol. 63,1; 2015. 319-27.

Priyanka Roy, Nandini Das (2017): Ultrasonic assisted synthesis of Bikitaite zeolite: A potential material for hydrogen storage application. Ultrasonics Sonochemistry, Volume 36, 2017. 466-473.

Ye, Yubin (2015): Effect of High Intensity Ultrasound on Crystallization Behavior and Functional Properties of Lipids. All Graduate Theses and Dissertations – Utah State University 2015.