*ราคาอาจมีการเปลี่ยนแปลงตามอัตราแลกเปลี่ยน โปรดสอบถาม Line : @siamintercorp

04 กรกฎาคม 2567

ผู้ชม 989 ผู้ชม

| Standards |

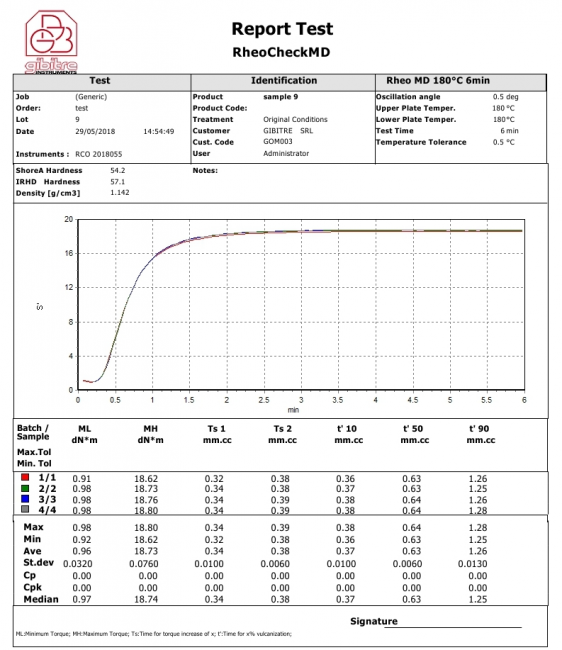

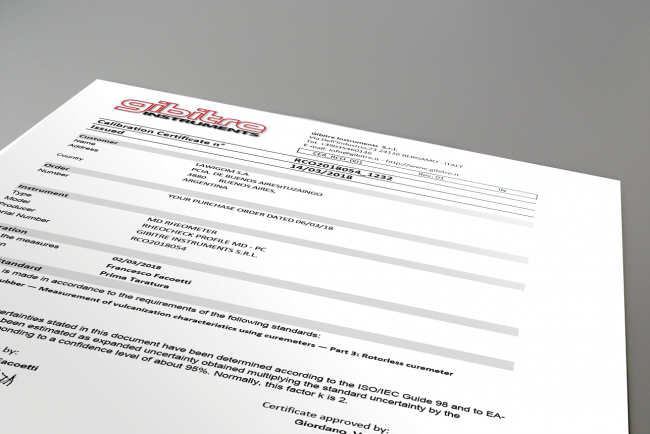

| Rubber & Elastomers Standards the instrument complies with: ASTM D5289 , ISO 6502-1 , ISO 6502-3 Note: compliance with some standards may require optional accesories or setups. |

| References |

| Gibitre RheoCheck is currently installed in 39 countries |

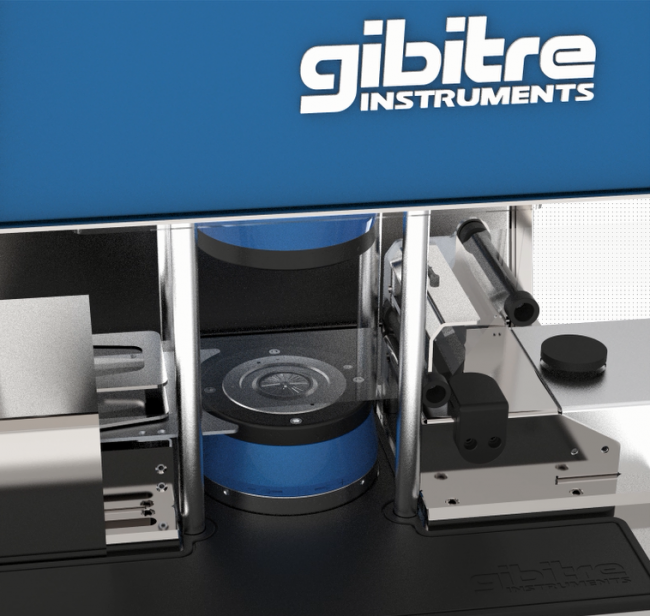

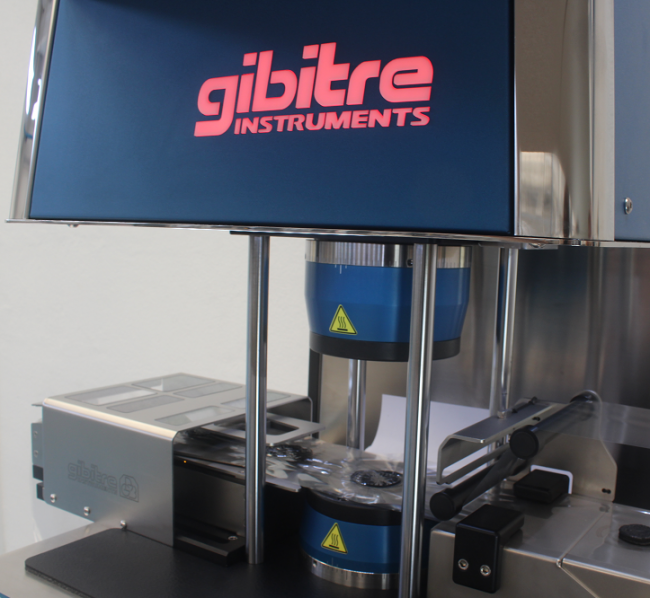

| Why Choose Rheocheck MD - Drive? | ||||||

|

||||||

|

||||||||||

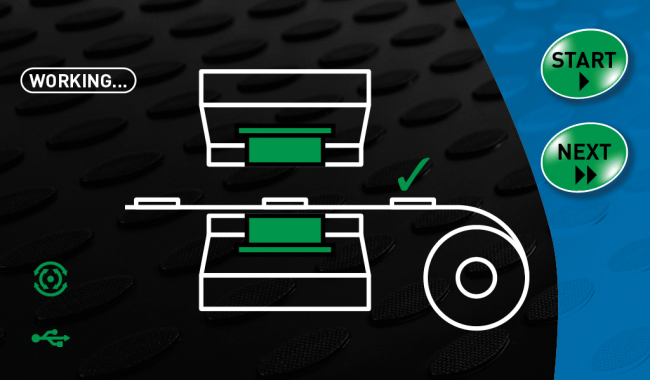

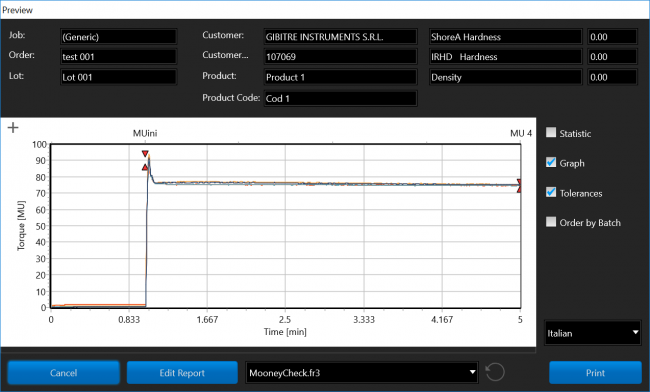

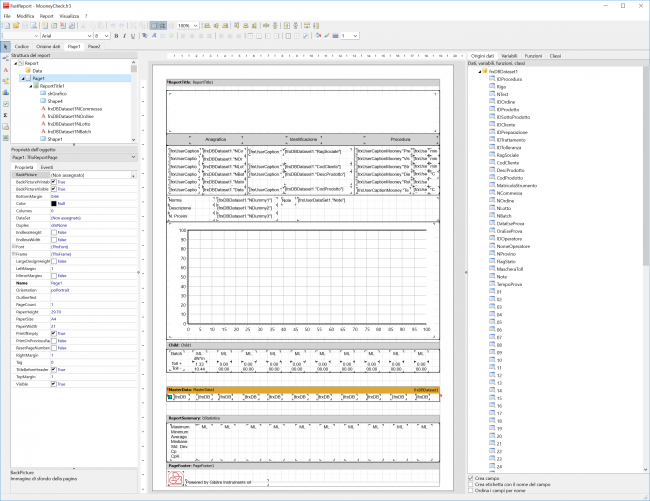

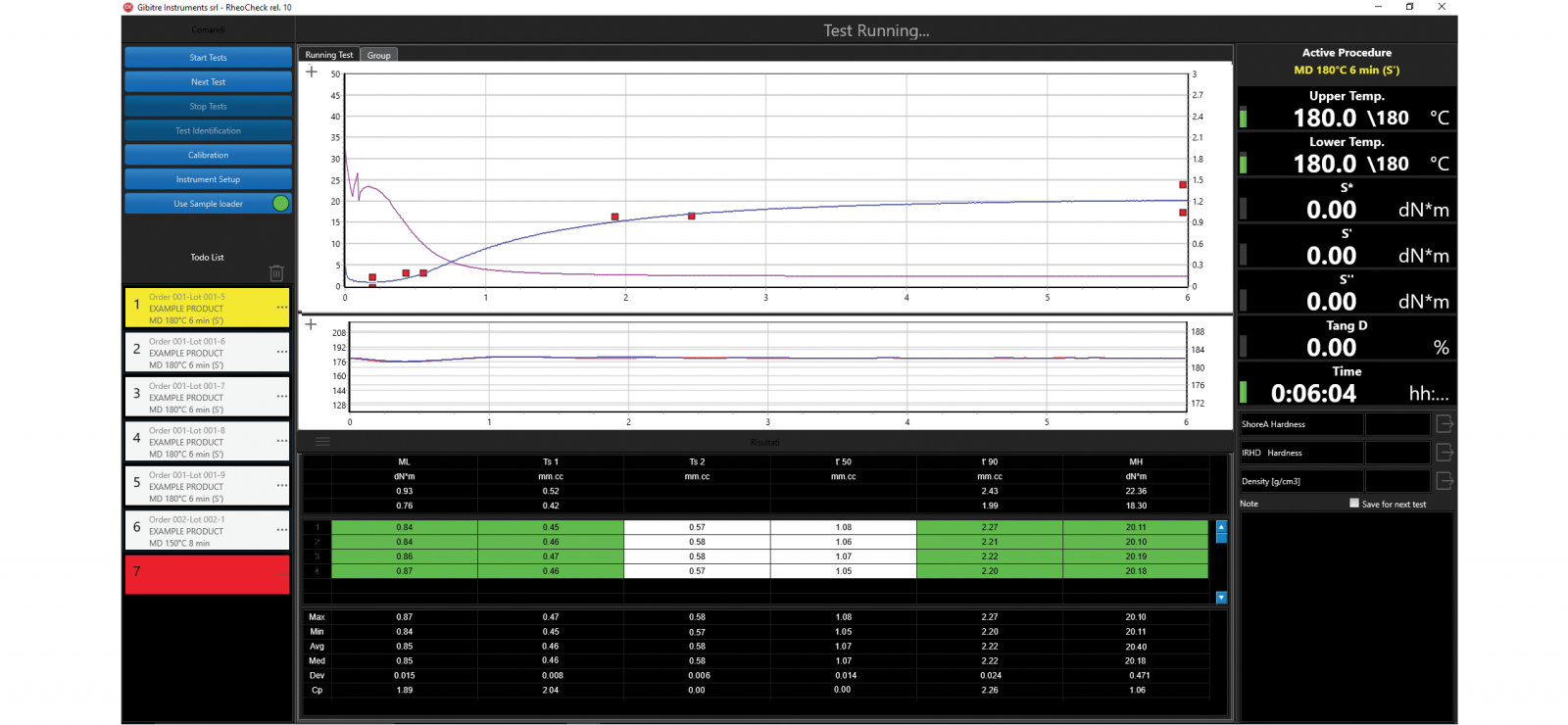

Software

|

|

|||||||||

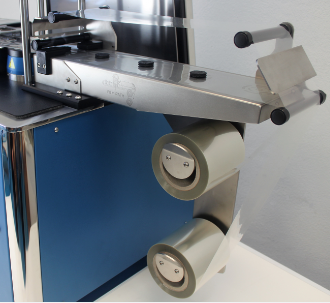

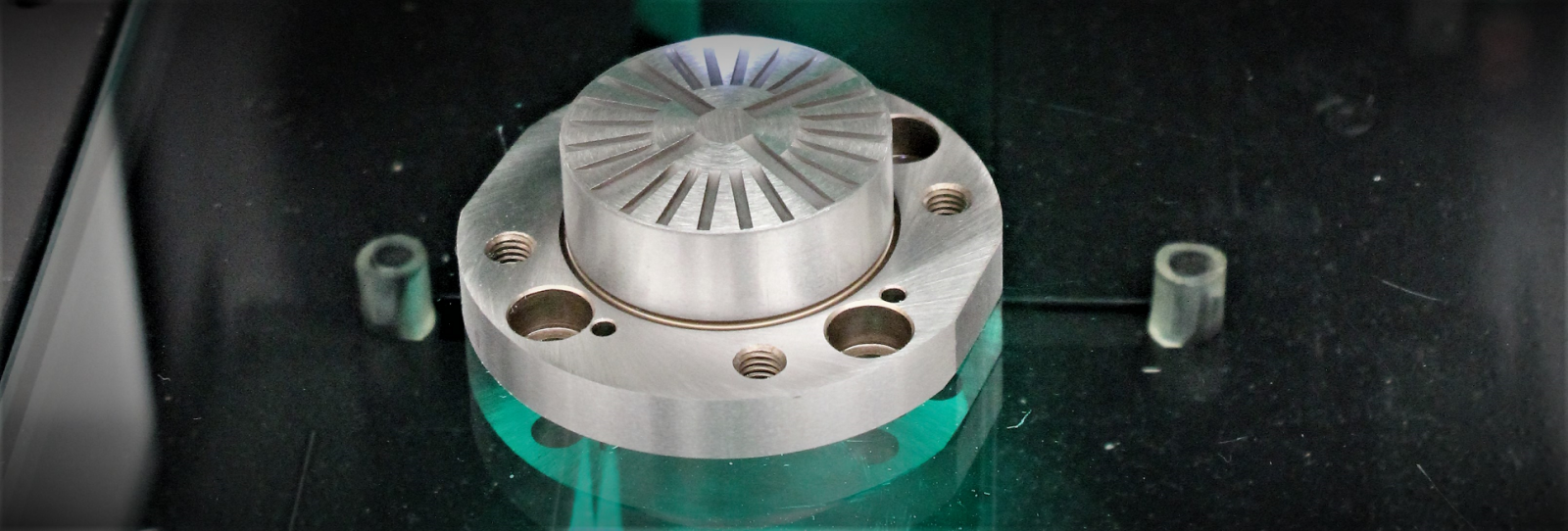

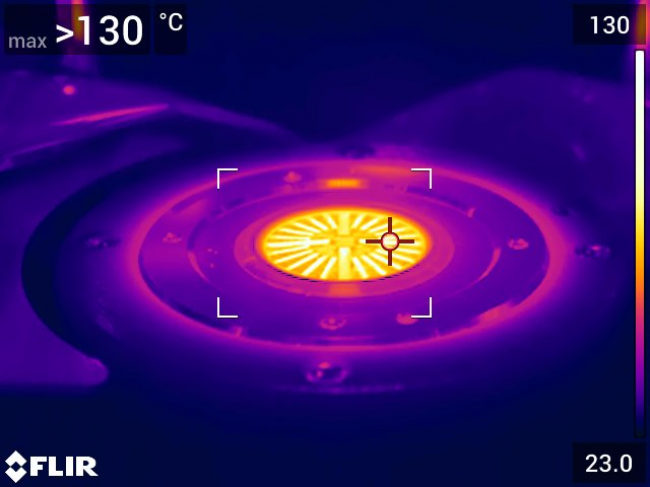

Attention to every detail

|

|

||||||||||||||||||||||||||||||

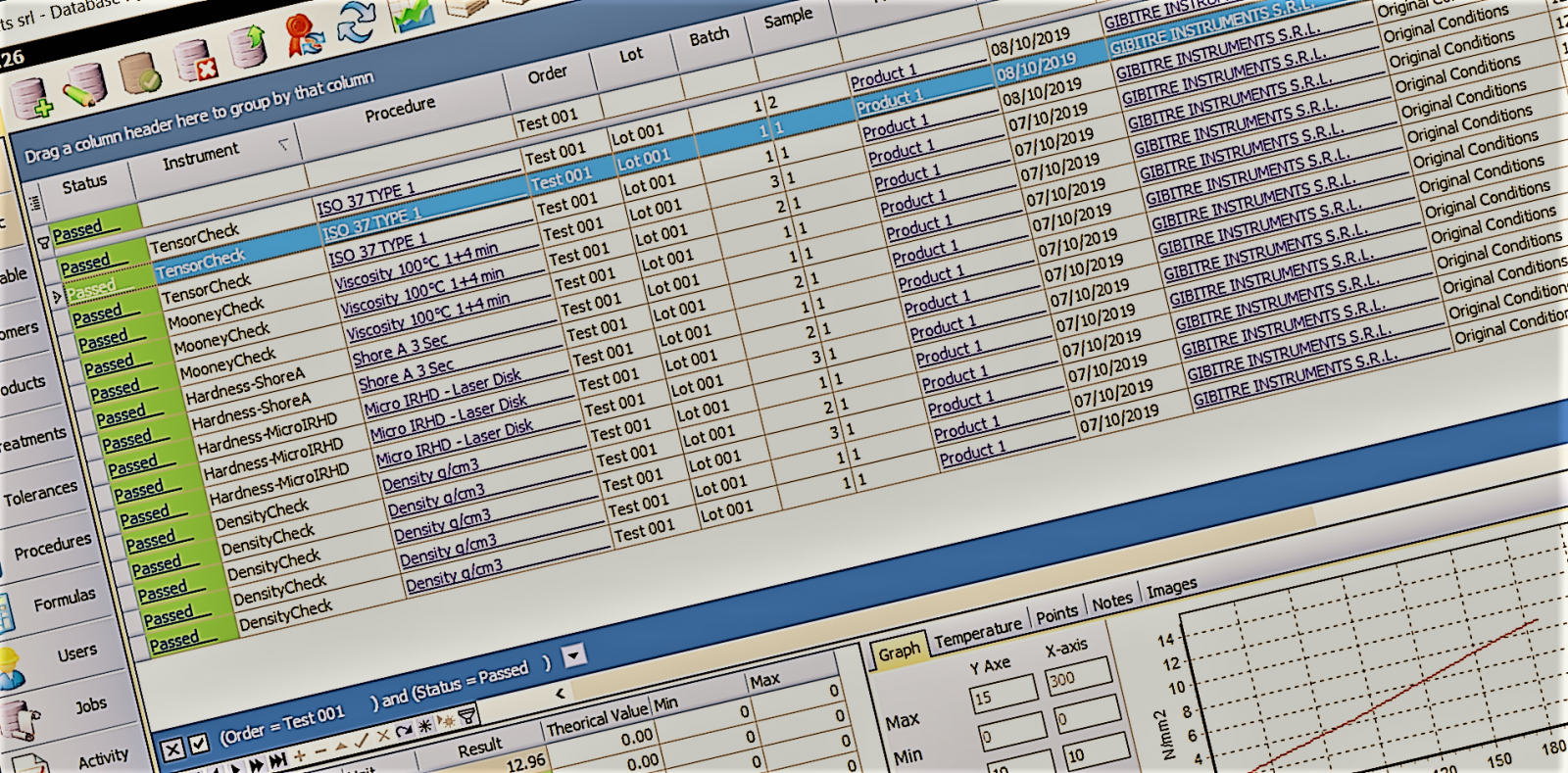

Data Management

|

||||||||||||||||||||||||||||||

Accessories

|

Download

|