*ราคาอาจมีการเปลี่ยนแปลงตามอัตราแลกเปลี่ยน โปรดสอบถาม Line : @siamintercorp

05 กรกฎาคม 2567

ผู้ชม 728 ผู้ชม

| Standards |

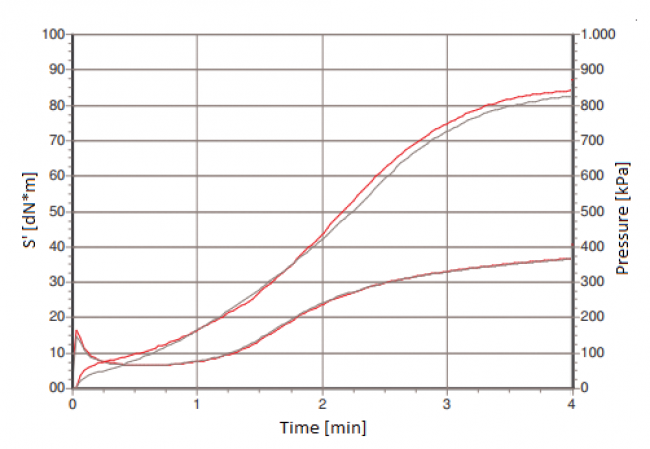

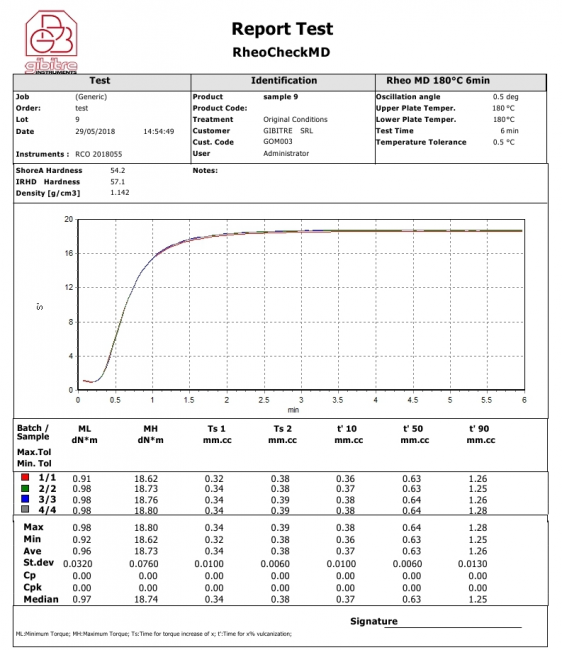

| Rubber & Elastomers Standards the instrument complies with: ASTM D2084 , ISO 6502-1 , ISO 6502-2 Note: compliance with some standards may require optional accesories or setups. |

| References |

| Gibitre RheoCheck is currently installed in 39 countries |

|

||||||||||

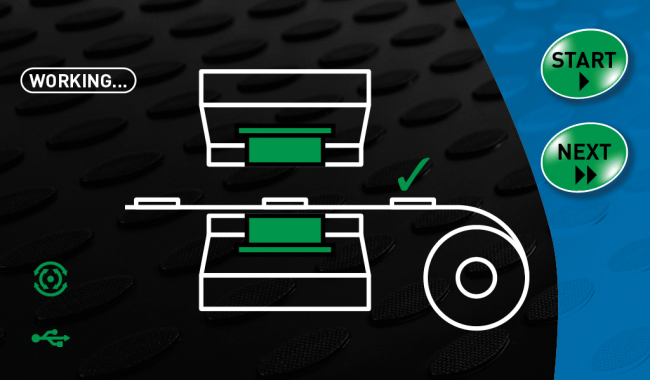

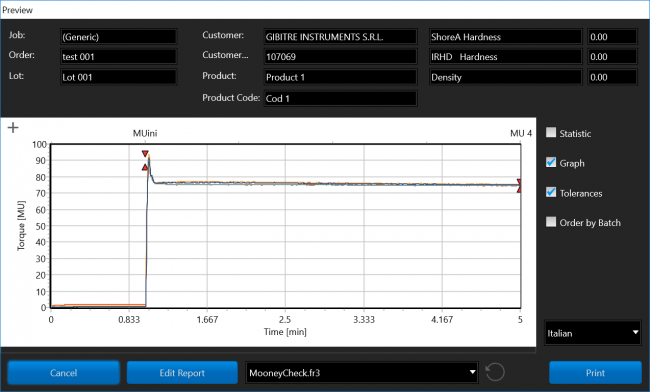

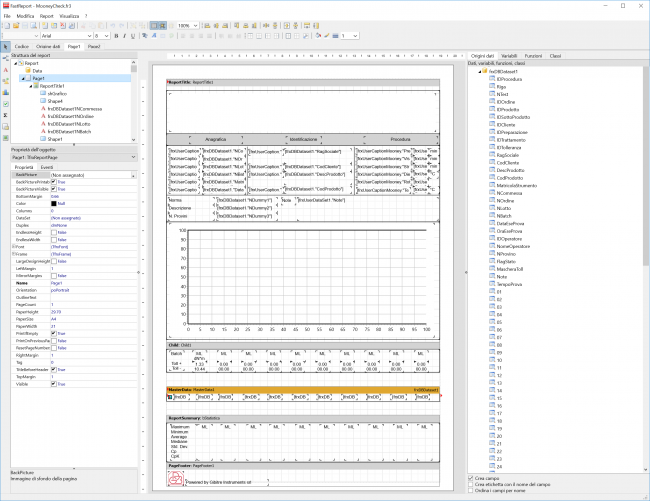

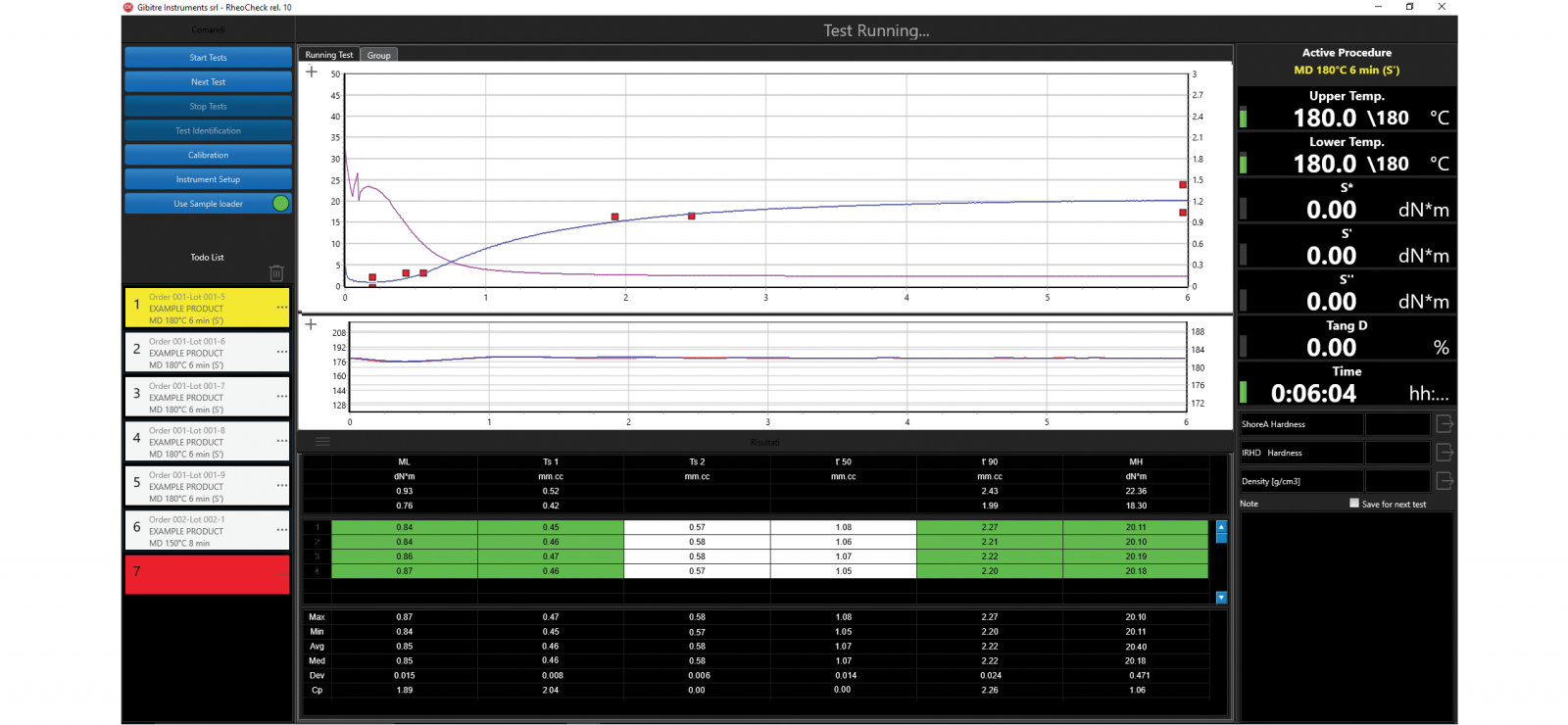

Software

|

Designed for the user

|

|

|||||||||||||||||||||||||||

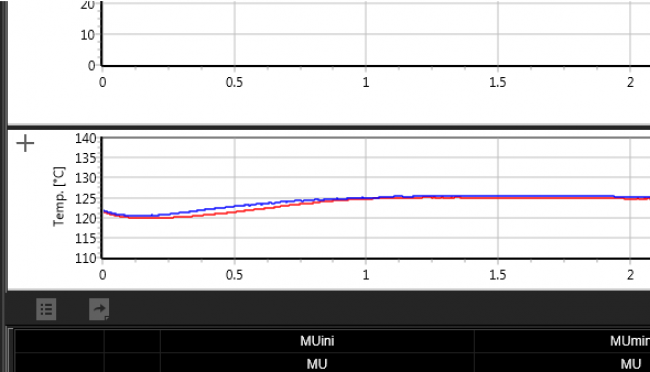

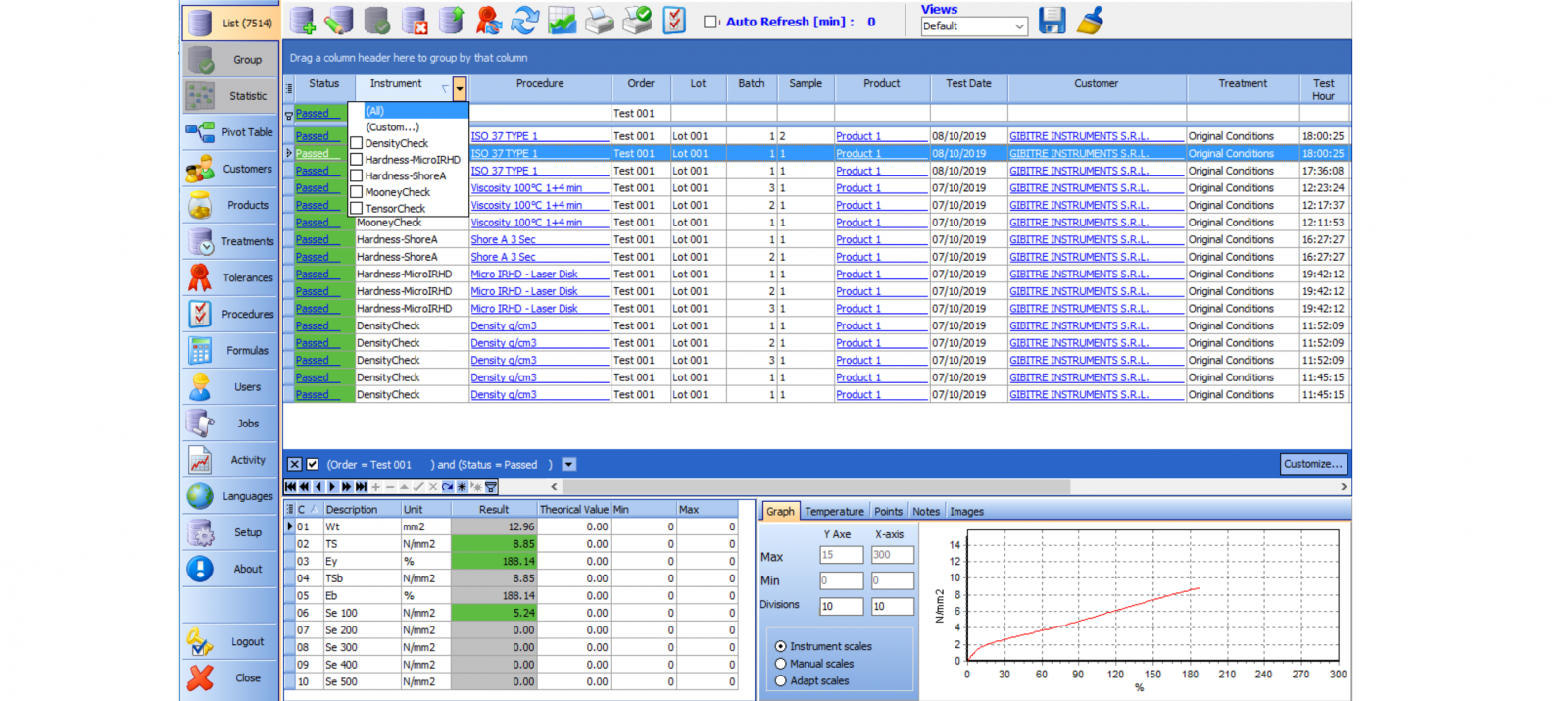

Data Management

|

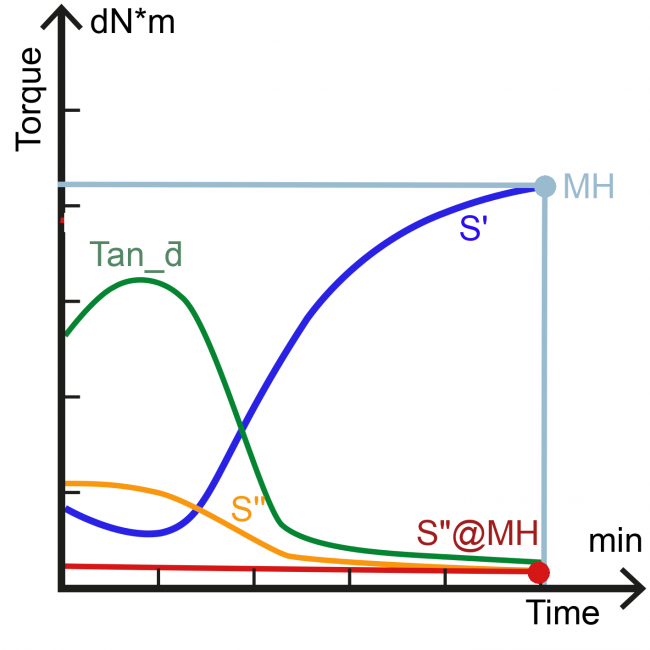

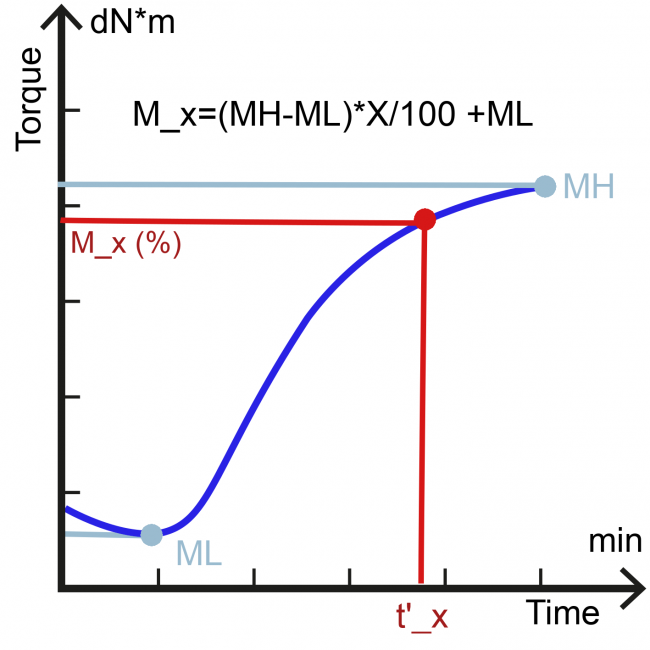

| Technical specification | ||||||||||||||||||||||||||||||||||||||||||||||

|

Reference Standards

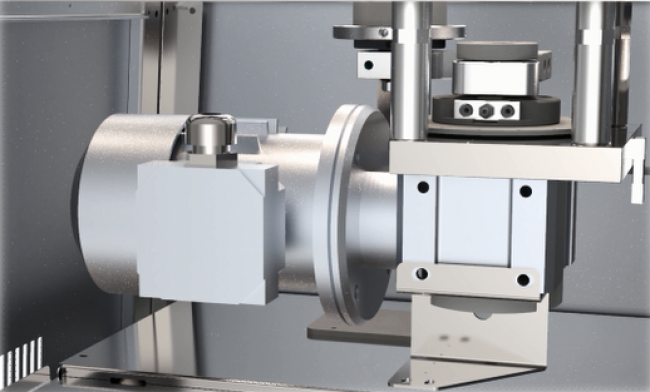

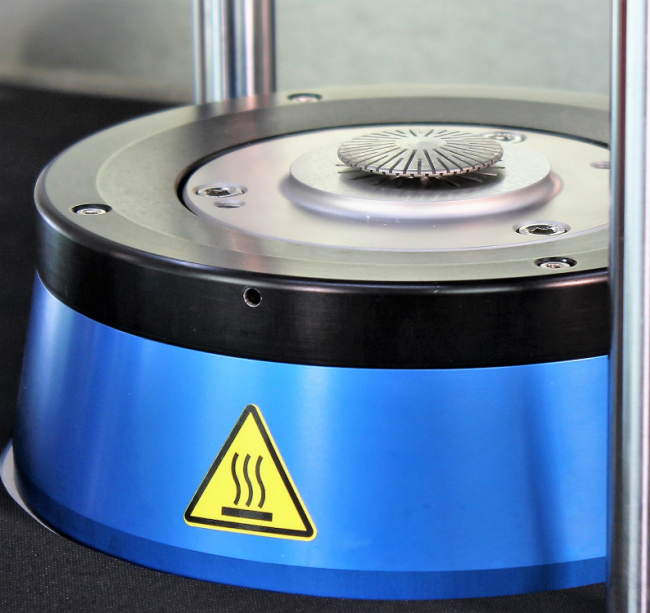

Instrument Characteristics

Software

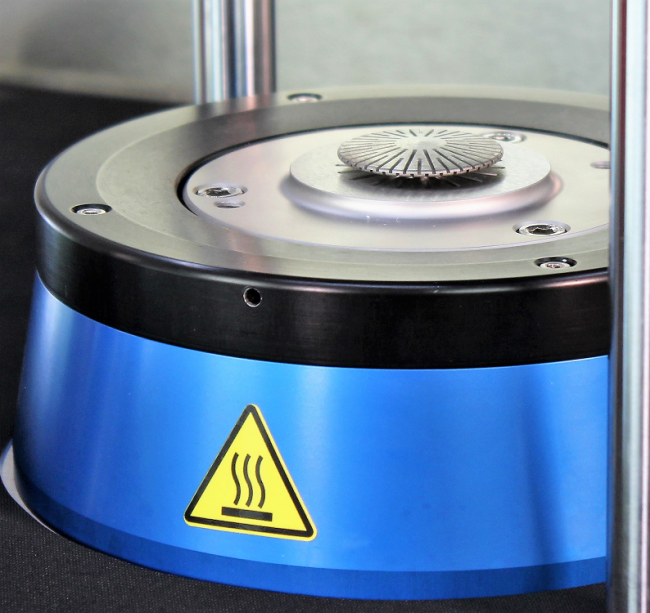

Safety Devices

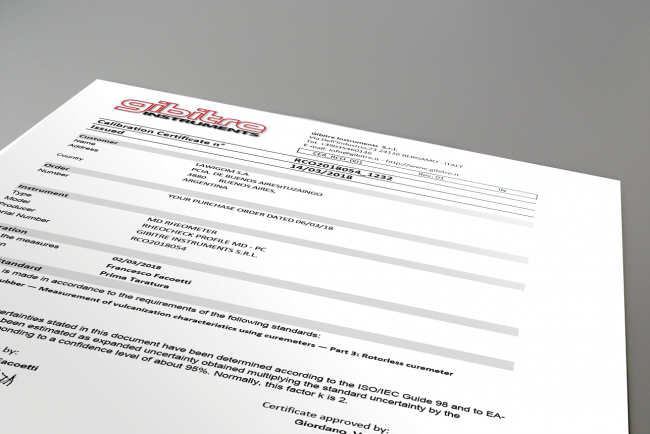

Calibration

Construction Characteristics

Personal Computer (optional)

|

FAQ

|

Download

|

| ขอใบเสนอราคา |

|---|