*ราคาอาจมีการเปลี่ยนแปลงตามอัตราแลกเปลี่ยน โปรดสอบถาม Line : @siamintercorp

08 กรกฎาคม 2567

ผู้ชม 1133 ผู้ชม

| Standards |

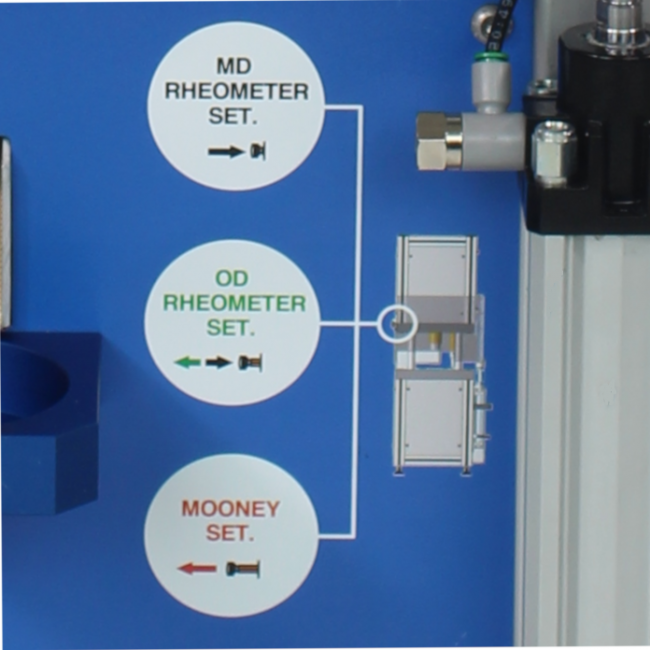

| Rubber & Elastomers Standards the instrument complies with: ISO 289-1, ISO 289-2, ISO 289-4, ASTM D1646, ASTM D2084, ASTM D5289, ISO 6502-1, ISO 6502-2, ISO 6502-3 Note: compliance with some standards may require optional accesories or setups. |

| References |

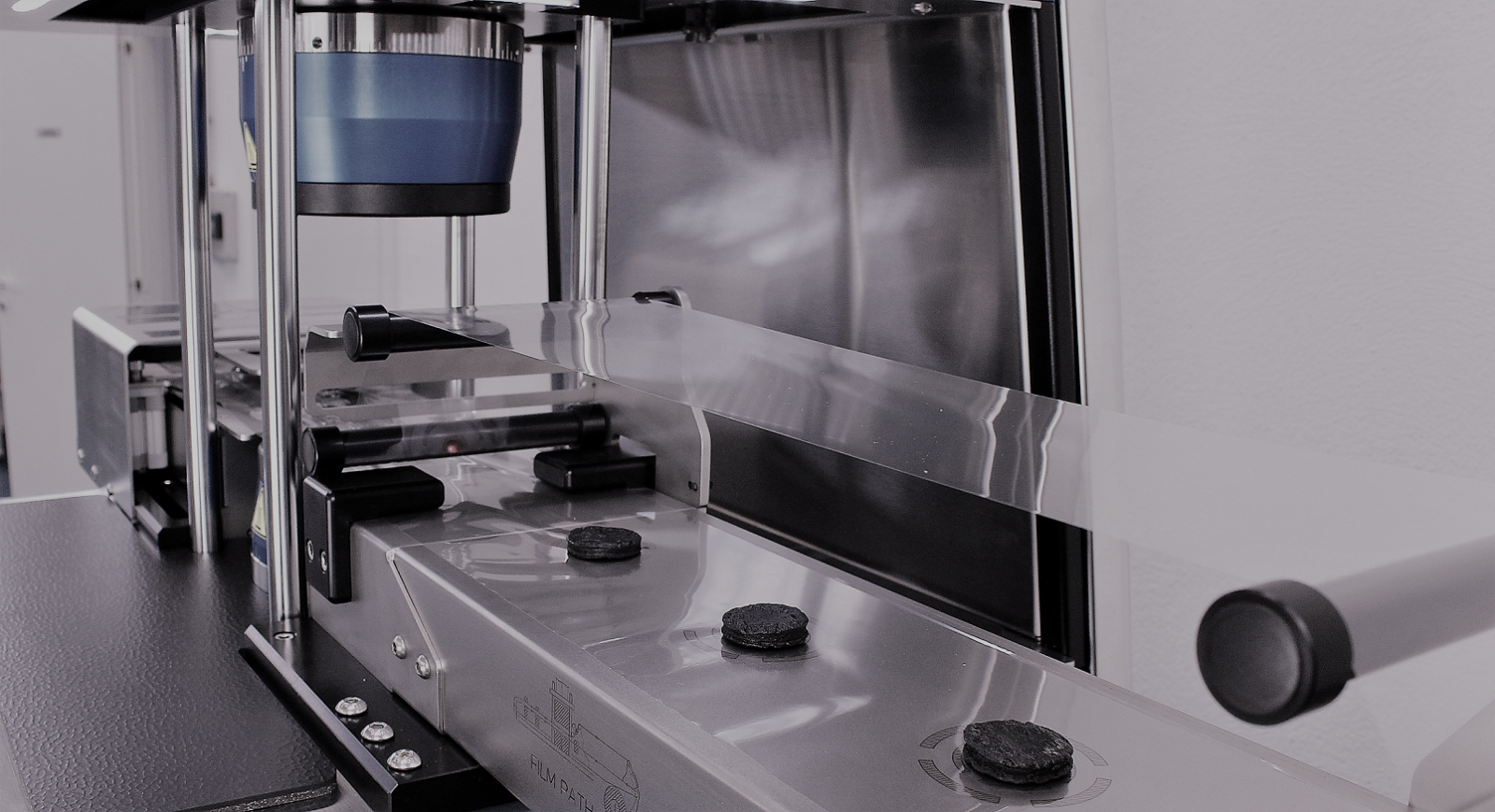

| Gibitre Constant Volume Sample Cutter is currently installed in 23 countries |

-------

| Technical specification | |||||||||||||||||||||

Reference Standards

|

Download

|

| ขอใบเสนอราคา |

|---|

| Reference Customer (กดที่โลโก้ เพื่อดูเว็บไซต์ของลูกค้าที่สั่งซื้อสินค้ากับทางบริษัท) | ||||

| อยู่ในระหว่างอัพเดทข้อมูล... | ||||