26 มกราคม 2567

ผู้ชม 3101 ผู้ชม

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Sealing strength tester Labormaster | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

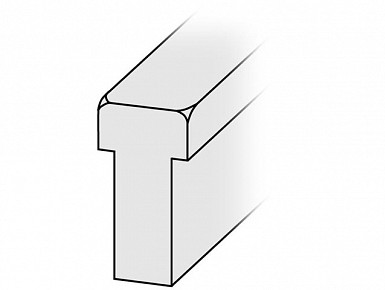

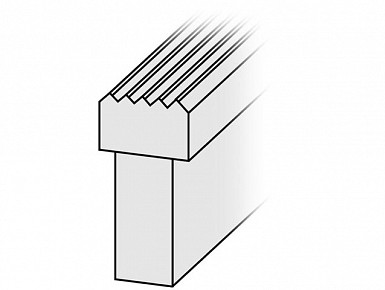

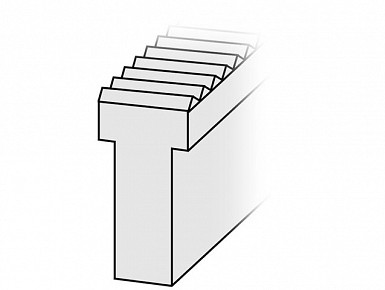

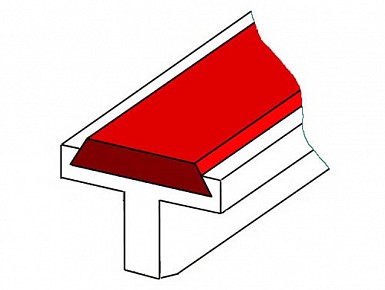

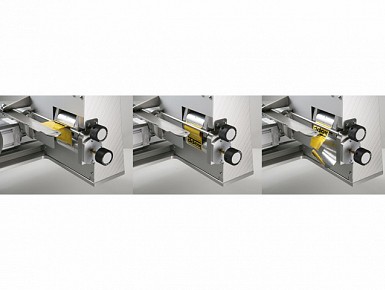

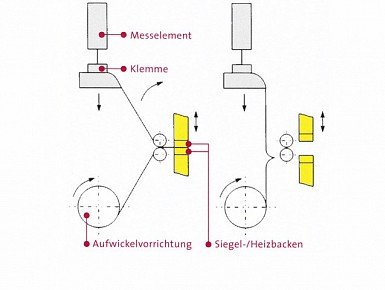

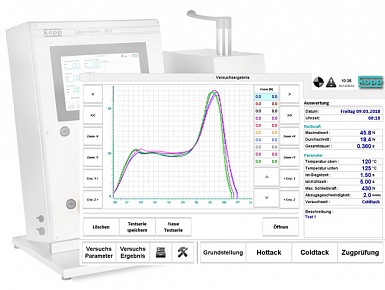

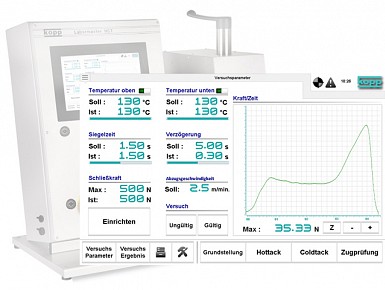

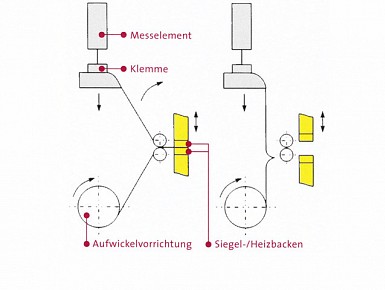

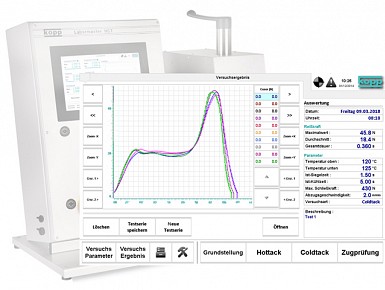

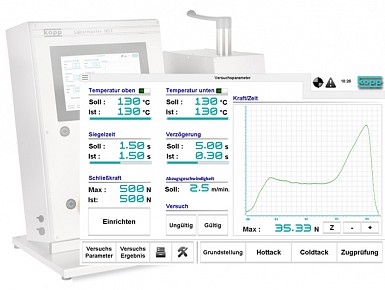

The KOPP Labormaster with integrated Laboratory-Sealer SGPE is now available in the new version LABORMASTER 3200 with touchpanel. Made for measurement of sealing strength (strength of hot sealing and cold sealing / hot-tack and cold-tack) the KOPP Labormaster optimally combines the functions of precise sealing, test of sealing strength, visualization, documentation and data logging. Hot-Tack with peel strength measuring devices |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ขอใบเสนอราคา |

|---|

| Reference Customer (กดที่โลโก้ เพื่อดูเว็บไซต์ของลูกค้าที่สั่งซื้อสินค้ากับทางบริษัท) | ||||

| อยู่ในระหว่างอัพเดทข้อมูล... | ||||

.jpg)