21 ตุลาคม 2567

ผู้ชม 944 ผู้ชม

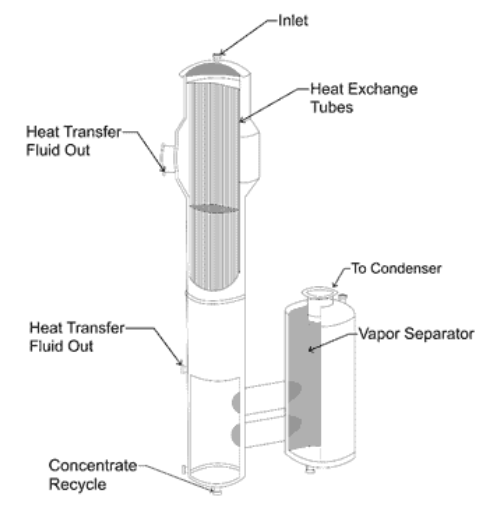

fracTron uses three independent falling film evaporators designed for rapid ethanol removal. Using vertical tube heat transfer exchangers in combination with packed bed reactors, the system supports a continuous solvent recycling system capacity of 40 gallons per hour. This allows producers to drastically increase the efficiency of their solvent removal distillation process while improving distillate quality.![]() Product Brochure

Product Brochure

fracTron-1000 FEATURES & BENEFITS

- Up to 40 gallons/hour Capacity

- 3-Stage Fractional Separation

- Inert Carrier Gas

- C1D2 Compliant

- UL698A Listed Components

PROCESSING POWER:

Continuous process flow reduces labor; Complete solvent removal eliminates secondary processing; Shorter run times, reduced downtime

GMP COMPLIANCE:

Lot, calibration and maintenance tracking; Barcode-enabled paper and electronic trail; VOC detector and alarms; Z-purged electronics for NFPA compliance; Easy clean-in-place capabilities; 21 CFR Part 11 compliant software

PROCESSING CONTROL:

Three stills independently controlled; Containment between stages; Programmable methods with user authentication; Out-of-operating-spec alarms; Mass flow tracking of yields; Data visualization and alarms; WiFi enabled monitoring and control

General Specifications

| Dimensions (inches) | L90″ x W37″ x H90″ |

| Footprint (square feet) | 25 |

| Unit Weight (pounds) | 2310.36 |

| Sound Pressure (db) | <60 |

CERTIFICATIONS:

UL 698A

REQUIRED, SOLD SEPARATELY:

Chiller (45 GPM, 230V/3ph/60 Hz); Heater (18kW, 18 GPM, 230V/3ph/60 Hz); Critical Spares Kit, #10-1064 (208-230V/380V); and Startup Kit, #10-1098 (208-230V/380V)

ALSO AVAILABLE, SOLD SEPARATELY:

GMP Documentation Package; Commissioning and Training Package; Maintenance Package (12 Months)

WARRANTY:

12 months for quality, labor, parts, and workmanship on United Science equipment.