Ideal for cutting acrylic, other plastics and low thickness steel

*ราคาอาจมีการเปลี่ยนแปลงตามอัตราแลกเปลี่ยน โปรดสอบถาม Line : @siamintercorp

07 มิถุนายน 2567

ผู้ชม 2153 ผู้ชม

|

|

| MECALASE | |

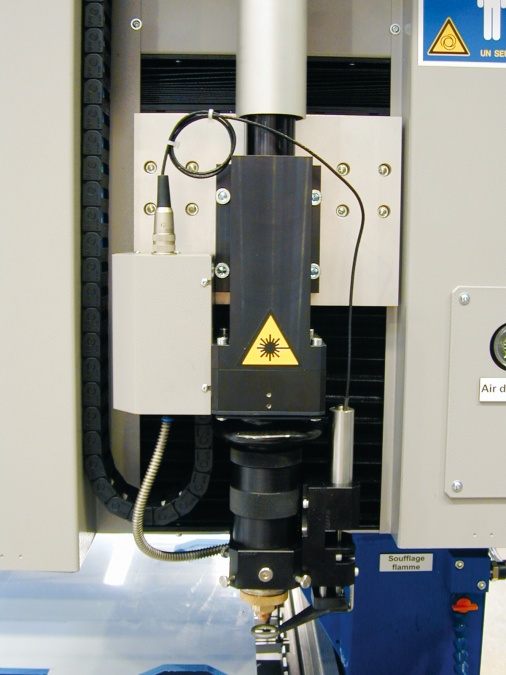

| Fixed table, mobile laser, average power. Sealed laser sources from 100 to 600W enable to get a very low operating cost because these laser do not require exterior laser gas and they have a life time of 15000 to 18000 hours, before any gas reloading. | |

| CUTTING EQUIPMENT OPTIMIZED FOR MACHINING OF FOLLOWING MATERIALS WITH STANDARD FOCUSING HEADS : |

|

| • Acrylic • Plastic materials • Wood and by-products |

|

| THE UTILIZATION OF A FOCUSING HEAD WITH HIGH PRESSURE LENS GIVES THE POSSIBILITY TO CUT IN ADDITION : |

|

| • Soft steel : thickness 4 mm with 300W, 6 mm with 600W • Stainless steel : thickness 1,5 mm with 350W, 3 mm with 600W Fast, rigid and accurate equipment, three available sizes in standard |

|

| TECHNOLOGIES : | |

| • Transmission by 4 ball screws (2 ball screws on X axes), numerical Z axis • Motorisation : 4 DC servomotors with continuous current • Guidance : precision linear rails with preloaded ball slides • Numerical control : Power Automation MECANUMERIC CN7000, ISO code • Sealed CO2 laser driven under mobile gantry and only one reversing mirror towards the focusing head : easy maintenance and low operating cost. • FOMEC focusing head : focus lens 2,5 or 5 inches with coaxial suction • Fume suctions by table divided into sectors with automatic zone selection • Standard table in anodized aluminium bars and anti reflecting profiles • Numerous CO2 laser sources available |

|

| MAIN FEATURES : | |

| • Maximum speed in mm/sec : 250 • Passage under gantry in mm : 185 • Resolution in mm : 0,005 • Repeatability in mm : +/-0,05 to 20° C |

|

| OPTIONS : | |

| • Vision registration/compensation system by camera (GTK, OPTISCOUT) • PRECITEC high pressure focusing head PRECITEC for steel cutting. • Filtration system and fume treatment. • Aluminium honeycomb special tables. • Interchangeable tables for loading / unloading in concealed time. • Automatic compensation system of flatness defects. • SIEMENS numerical control and SIEMENS servomotors. • Complete safety enclosure. |

|

| Travel in mm | X | Y | Z |

| MECALASE ML 3015 | 3050 | 1510 | 195 |

| MECALASE ML 3020 | 3050 | 2020 | 195 |

| Reference Customer (กดที่โลโก้ เพื่อดูเว็บไซต์ของลูกค้าที่สั่งซื้อสินค้ากับทางบริษัท) | ||||

| อยู่ในระหว่างอัพเดทข้อมูล... | ||||